Oil Pressure Gauge

INSPECTION OF OIL PRESSURE GAUGE

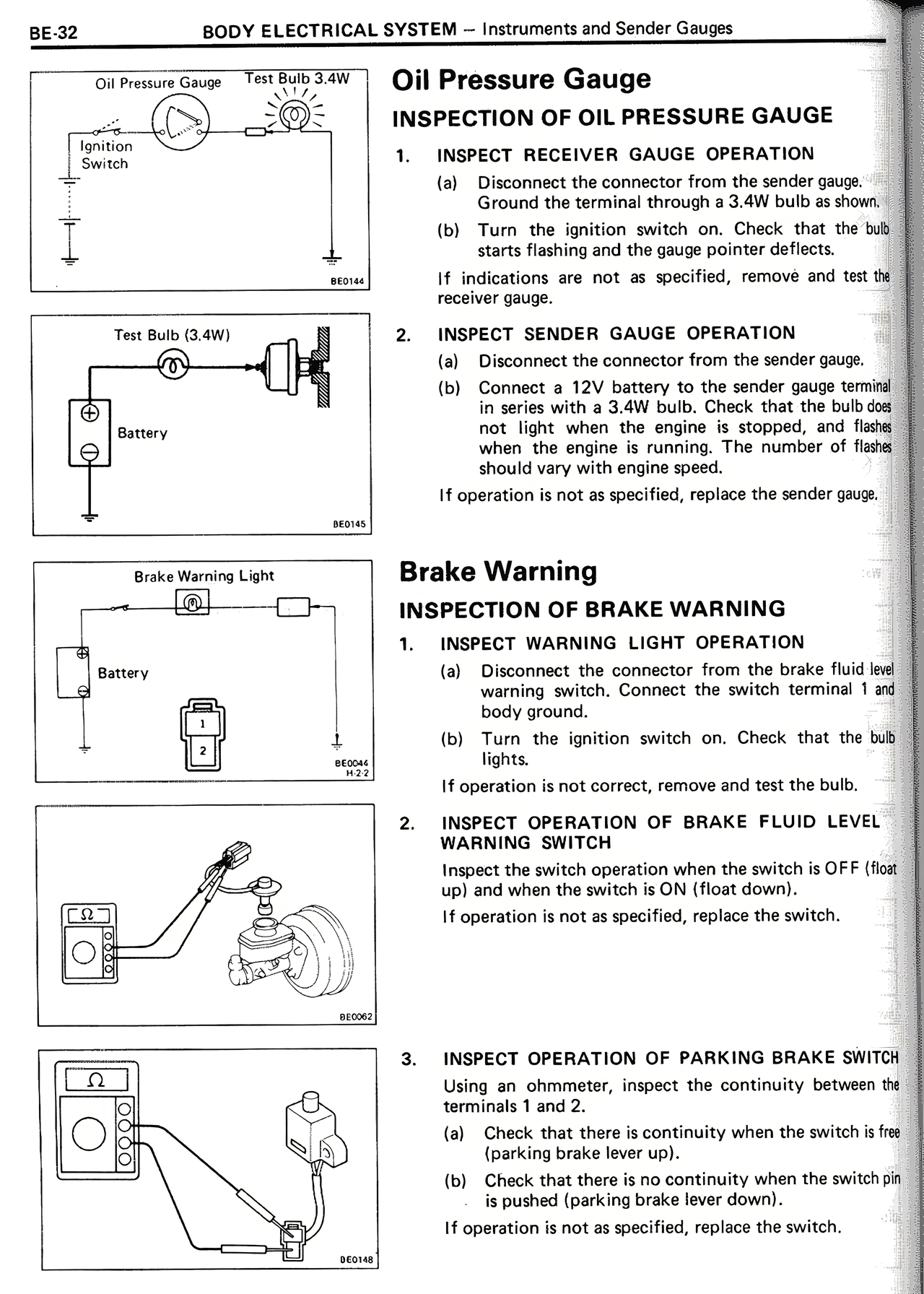

1. INSPECT RECEIVER GAUGE OPERATION

(a) Disconnect the connector from the sender gauge. Ground the terminal through a 3.4W bulb as shown.

(b) Turn the ignition switch on. Check that the bulb starts flashing and the gauge pointer deflects.

If indications are not as specified, remove and test the receiver gauge.

2. INSPECT SENDER GAUGE OPERATION

(a) Disconnect the connector from the sender gauge.

(b) Connect a 12V battery to the sender gauge terminal in series with a 3.4W bulb. Check that the bulb does not light when the engine is stopped, and flashes when the engine is running. The number of flashes should vary with engine speed.

If operation is not as specified, replace the sender gauge.

Brake Warning

INSPECTION OF BRAKE WARNING

1. INSPECT WARNING LIGHT OPERATION

(a) Disconnect the connector from the brake fluid level warning switch. Connect the switch terminal 1 and body ground.

(b) Turn the ignition switch on. Check that the bulb lights.

If operation is not correct, remove and test the bulb.

2. INSPECT OPERATION OF BRAKE FLUID LEVEL WARNING SWITCH

Inspect the switch operation when the switch is OFF (float up) and when the switch is ON (float down).

If operation is not as specified, replace the switch.

3. INSPECT OPERATION OF PARKING BRAKE SWITCH

Using an ohmmeter, inspect the continuity between the terminals 1 and 2.

(a) Check that there is continuity when the switch is free (parking brake lever up).

(b) Check that there is no continuity when the switch pin is pushed (parking brake lever down).

If operation is not as specified, replace the switch.