EC-6 EMISSION CONTROL SYSTEMS — Fuel Evaporative Emission Control (EVAP) System

INSPECTION OF CHARCOAL CANISTER

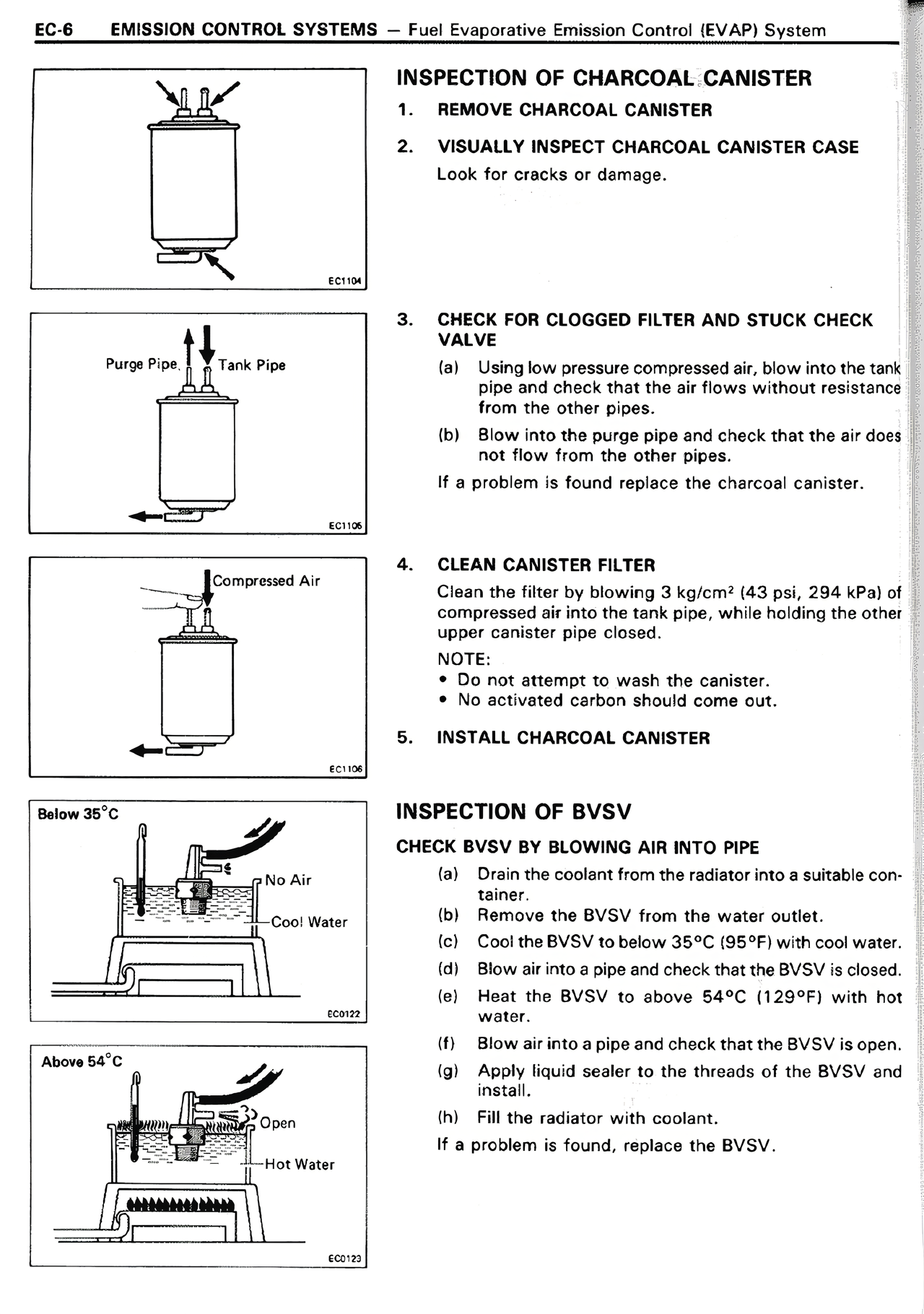

1. REMOVE CHARCOAL CANISTER

2. VISUALLY INSPECT CHARCOAL CANISTER CASE

Look for cracks or damage.

3. CHECK FOR CLOGGED FILTER AND STUCK CHECK VALVE

(a) Using low pressure compressed air, blow into the tank pipe and check that the air flows without resistance from the other pipes.

(b) Blow into the purge pipe and check that the air does not flow from the other pipes.

If a problem is found replace the charcoal canister.

4. CLEAN CANISTER FILTER

Clean the filter by blowing 3 kg/cm² (43 psi, 294 kPa) of compressed air into the tank pipe, while holding the other upper canister pipe closed.

NOTE:

• Do not attempt to wash the canister.

• No activated carbon should come out.

5. INSTALL CHARCOAL CANISTER

INSPECTION OF BVSV

CHECK BVSV BY BLOWING AIR INTO PIPE

(a) Drain the coolant from the radiator into a suitable container.

(b) Remove the BVSV from the water outlet.

(c) Cool the BVSV to below 35°C (95°F) with cool water.

(d) Blow air into a pipe and check that the BVSV is closed.

(e) Heat the BVSV to above 54°C (129°F) with hot water.

(f) Blow air into a pipe and check that the BVSV is open.

(g) Apply liquid sealer to the threads of the BVSV and install.

(h) Fill the radiator with coolant.

If a problem is found, replace the BVSV.