INSPECTION OF IDLE SPEED

1. INITIAL CONDITIONS

(a) Air cleaner installed

(b) Normal engine operating temperature

(c) All pipes and hoses of air intake system connected

(d) All accessories switched off

(e) All vacuum lines properly connected (i.e., EGR systems, etc.)

(f) EFI system wiring connectors fully plugged

(g) Ignition timing set correctly

(h) Transmission in N range

2. CHECK IDLE SPEED

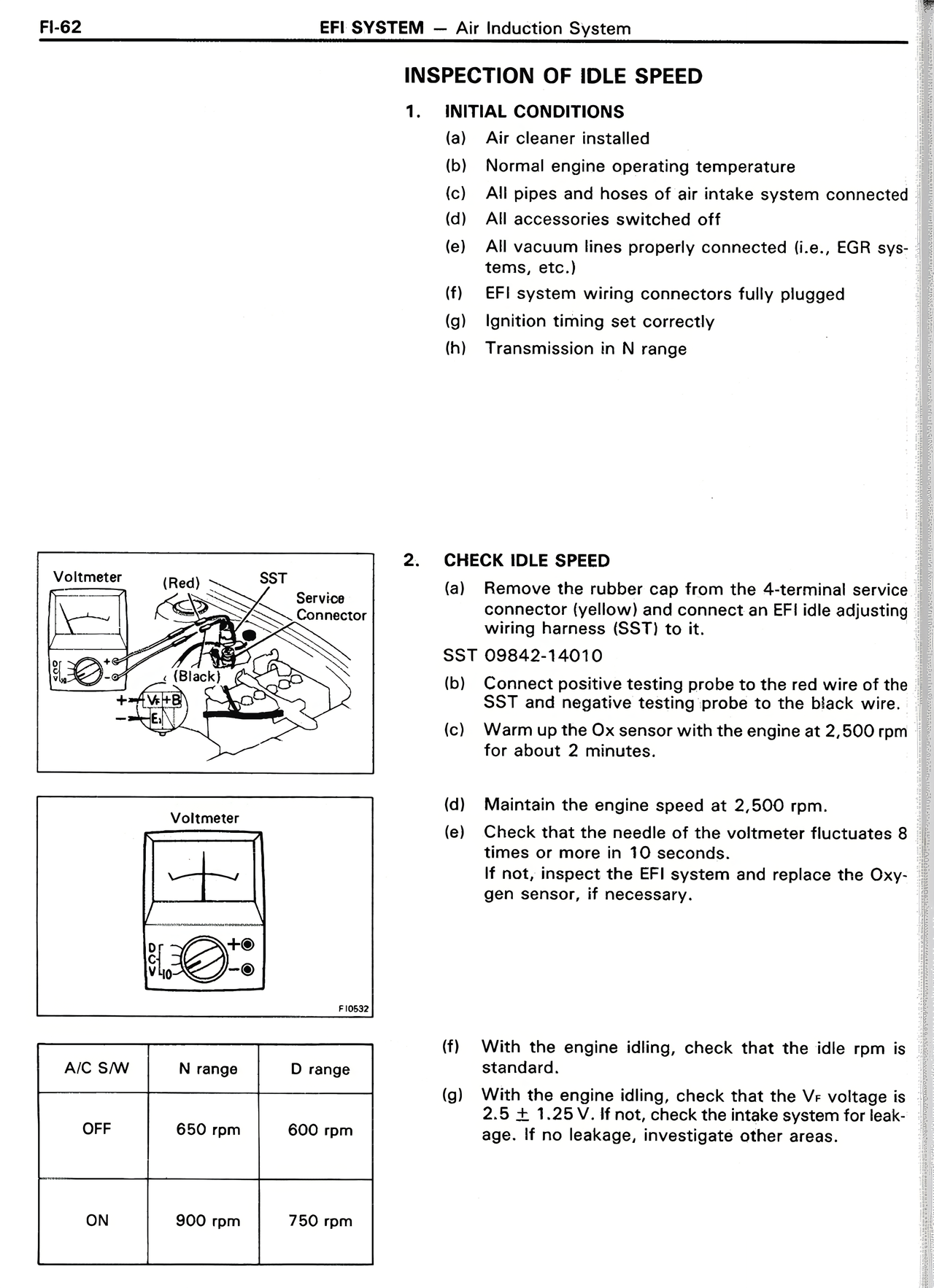

(a) Remove the rubber cap from the 4-terminal service connector (yellow) and connect an EFI idle adjusting wiring harness (SST) E1.

SST 09842-14010

(b) Connect positive testing probe to the red wire of the SST and negative testing probe to the black wire.

(c) Warm up the O2 sensor by running the engine at 2,500 rpm for about 2 minutes.

(d) Maintain the engine speed at 2,500 rpm.

(e) Check that the needle of the voltmeter fluctuates 8 times or more in 10 seconds.

If not, inspect the EFI system and replace the Oxygen sensor, if necessary.

(f) With the engine idling, check that the idle rpm is standard.

(g) With the engine idling, check that the VF voltage is 2.5 ± 1.25 V. If not, check the intake system for leakage. If no leakage, investigate other areas.

A/C S/W | N range | D range

OFF | 650 rpm | 600 rpm

ON | 900 rpm | 750 rpm