IGNITION SYSTEM — On-Vehicle Inspection

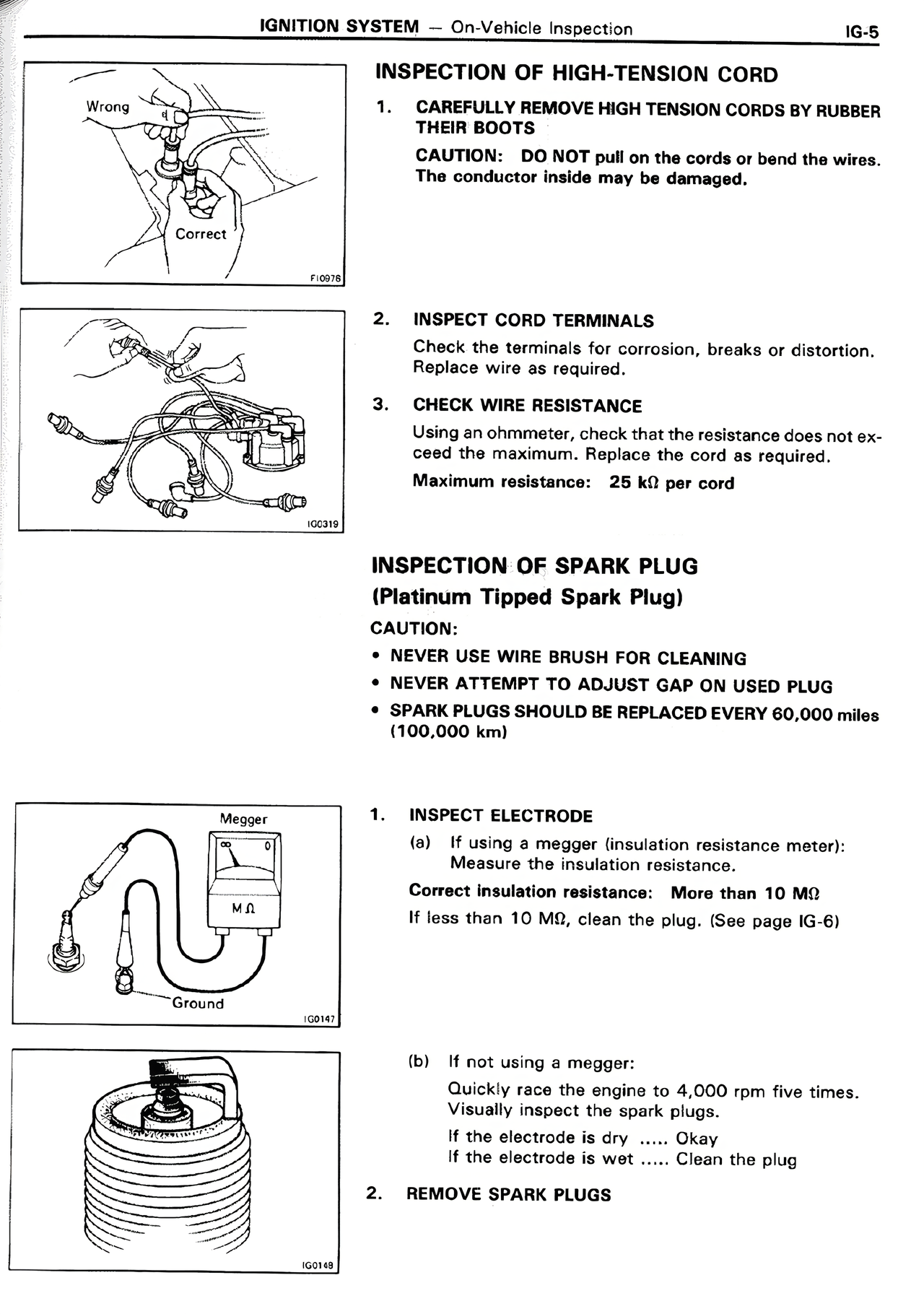

INSPECTION OF HIGH-TENSION CORD

1. CAREFULLY REMOVE HIGH TENSION CORDS BY RUBBER

THEIR BOOTS

CAUTION: DO NOT pull on the wires.

The conductor inside may be damaged.

2. INSPECT CORD TERMINALS

Check the terminals for corrosion, breaks or distortion.

Replace wire as required.

3. CHECK WIRE RESISTANCE

Using an ohmmeter, check that the resistance does not exceed the maximum. Replact the cord as required.

Maximum resistance: 25 kΩ per cord

INSPECTION OF SPARK PLUG

(Platinum Tipped Spark Plug)

CAUTION:

• NEVER USE WIRE BRUSH FOR CLEANING

• NEVER ATTEMPT TO ADJUST GAP ON USED PLUG

• SPARK PLUGS SHOULD BE REPLACED EVERY 60,000 miles

(100,000 km)

1. INSPECT ELECTRODE

(a) If using a megger (high insulation resistance meter):

Measure the insulation resistance.

Correct insulation resistance: More than 10 MΩ

If less than 10 MΩ, clean the plug. (See page IG-6)

(b) If not using a megger:

Quickly race the engine to 4,000 rpm five times.

Visually inspect the spark plugs.

If the electrode is dry ..... Okay

If the electrode is wet ..... Clean the plug

2. REMOVE SPARK PLUGS