MA-6 MAINTENANCE — Maintenance Operations

[DIAGRAM: Charcoal canister showing Air, B, C ports with text "Air should flow through freely and no charcoal should come out."]

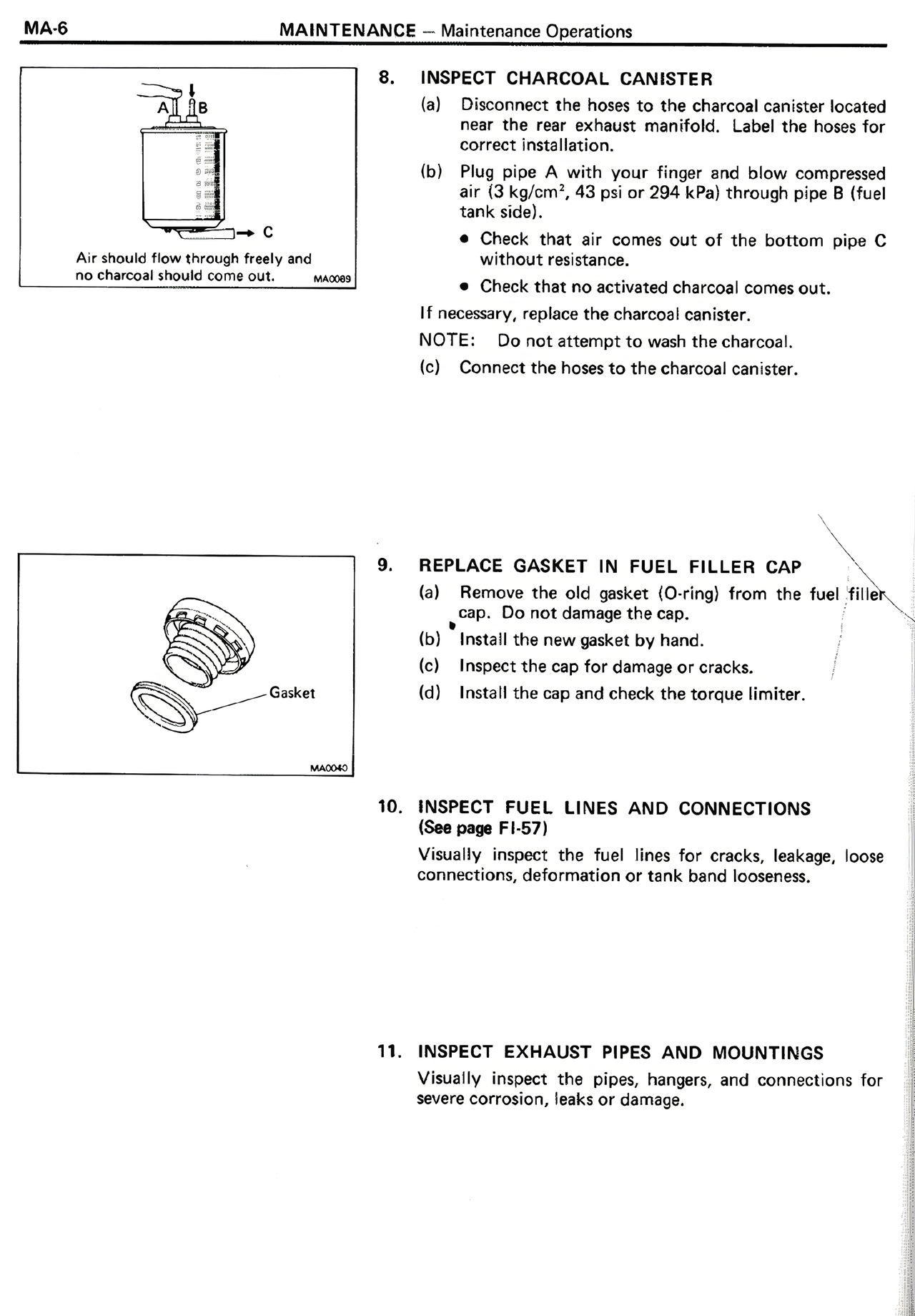

8. INSPECT CHARCOAL CANISTER

(a) Disconnect the hoses to the charcoal canister located near the rear exhaust manifold. Label the hoses for correct installation.

(b) Plug pipe A with your finger and blow compressed air (3 kg/cm², 43 psi or 294 kPa) through pipe B (fuel tank side).

• Check that air comes out of the bottom pipe C without resistance.

• Check that no activated charcoal comes out.

If necessary, replace the charcoal canister.

NOTE: Do not attempt to wash the charcoal.

(c) Connect the hoses to the charcoal canister.

[DIAGRAM: Fuel filler cap with gasket labeled]

9. REPLACE GASKET IN FUEL FILLER CAP

(a) Remove the old gasket (O-ring) from the fuel filler cap. Do not damage the cap.

(b) Install the new gasket by hand.

(c) Inspect the cap for damage or cracks.

(d) Install the cap and check the torque limiter.

10. INSPECT FUEL LINES AND CONNECTIONS

(See page FI-57)

Visually inspect the fuel lines for cracks, leakage, loose connections, deformation or tank band looseness.

11. INSPECT EXHAUST PIPES AND MOUNTINGS

Visually inspect the pipes, hangers, and connections for severe corrosion, leaks or damage.