(i) Check the ring gear runout.

Maximum runout: 0.07 mm (0.0028 in.)

Install the differential case onto the carrier and tighten the adjusting nut just to where there is no play in the bearing.

ASSEMBLY OF DIFFERENTIAL

(See page RA-22)

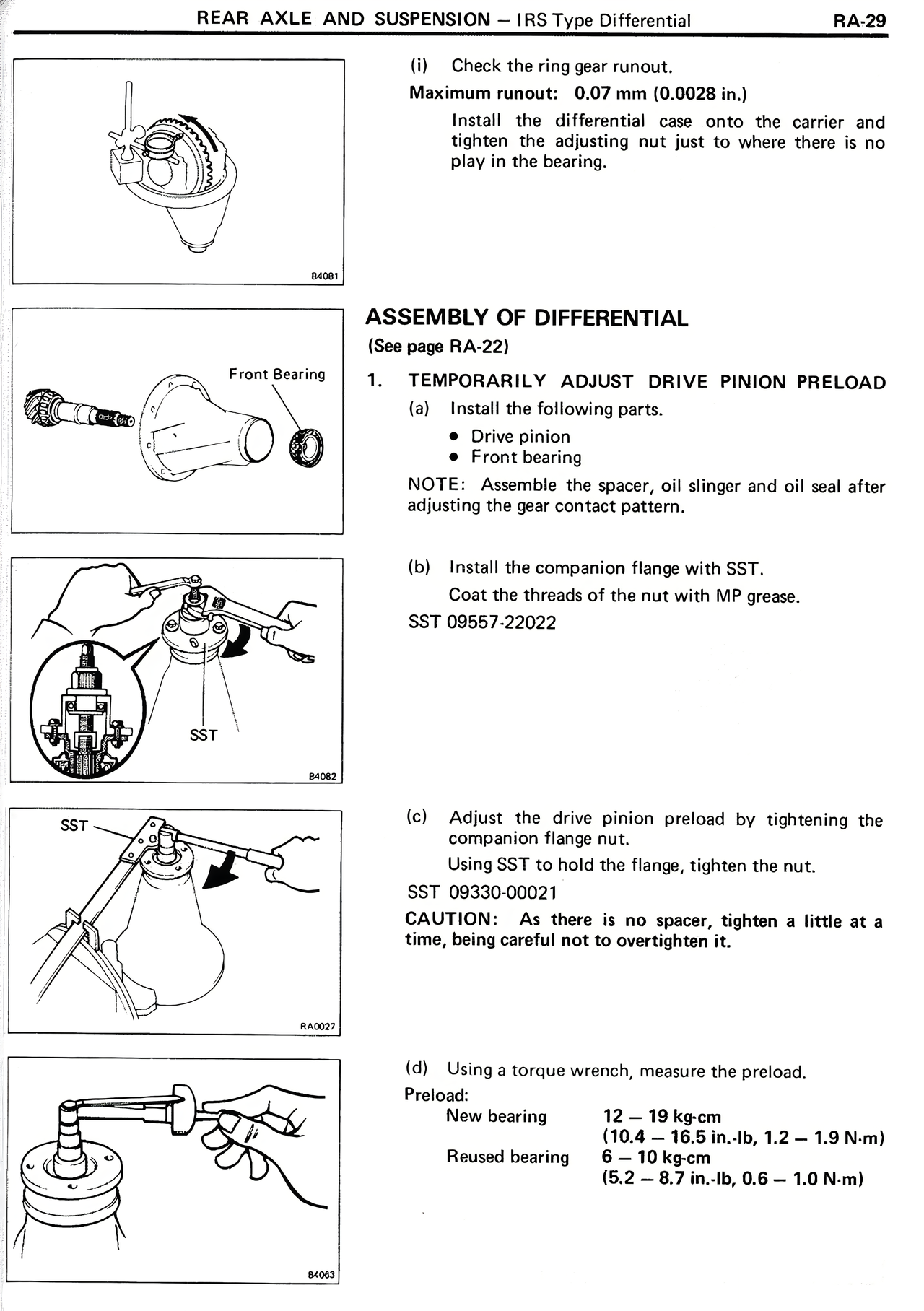

1. TEMPORARILY ADJUST DRIVE PINION PRELOAD

(a) Install the following parts.

• Drive pinion

• Front bearing

NOTE: Assemble the spacer, oil slinger and oil seal after adjusting the gear contact pattern.

(b) Install the companion flange with SST.

Coat the threads of the nut with MP grease.

SST 09557 22022

(c) Adjust the drive pinion preload by tightening the companion flange nut.

Using SST to hold the flange, tighten the nut.

SST 09330 00021

CAUTION: As there is no spacer, tighten a little at a time, being careful not to overtighten it.

(d) Using a torque wrench, measure the preload.

Preload:

New bearing 12 — 19 kg-cm

(10.4 — 16.5 in.-lb, 1.2 — 1.9 N-m)

Reused bearing 6 — 10 kg-cm

(5.2 — 8.7 in.-lb, 0.6 — 1.0 N-m)