EM-20

ENGINE MECHANICAL — Compression Check

COMPRESSION CHECK

HINT: If there is lack of power, excessive oil consumption or poor fuel economy, measure the cylinder compression pressure.

(7M-GE)

1. WARM UP ENGINE

2. DISCONNECT COLD START INJECTOR CONNECTOR

3. DISCONNECT HIGH-TENSION CORD FROM IGNITION COIL

4. REMOVE THROTTLE BODY

(a) Remove the PCV hose.

(b) Disconnect the water by-pass hoses and plug the hose end.

(c) Disconnect following hoses:

• VSV hose (for EGR)

• BVSV hose

• EGR vacuum modulator hoses

• No.7 air hose

(d) Disconnect the throttle position sensor connector.

(e) Remove the throttle body bracket.

(f) Remove the four bolts, throttle body and gasket.

5. REMOVE SPARK PLUGS

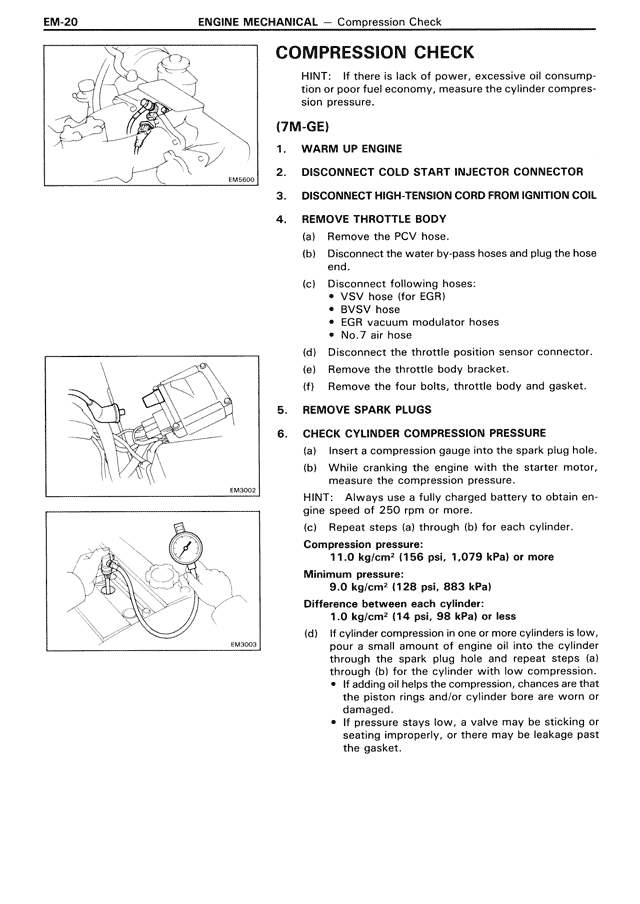

6. CHECK CYLINDER COMPRESSION PRESSURE

(a) Insert a compression gauge into the spark plug hole.

(b) While cranking the engine with the starter motor, measure the compression pressure.

HINT: Always use a fully charged battery to obtain engine speed of 250 rpm or more.

(c) Repeat steps (a) through (b) for each cylinder.

Compression pressure:

11.0 kg/cm² (156 psi, 1,079 kPa) or more

Minimum pressure:

9.0 kg/cm² (128 psi, 883 kPa)

Difference between each cylinder:

1.0 kg/cm² (14 psi, 98 kPa) or less

(d) If cylinder compression in one or more cylinders is low, pour a small amount of engine oil into the cylinder through the spark plug hole and repeat steps (a) through (b) for the cylinder with low compression.

• If adding oil helps the compression, chances are that the piston rings and/or cylinder bore are worn or damaged.

• If pressure stays low, a valve may be sticking or seating improperly, or there may be leakage past the gasket.