ENGINE MECHANICAL — Cylinder Block EM-71

← Front

[Diagram showing 6 pistons numbered 1-6]

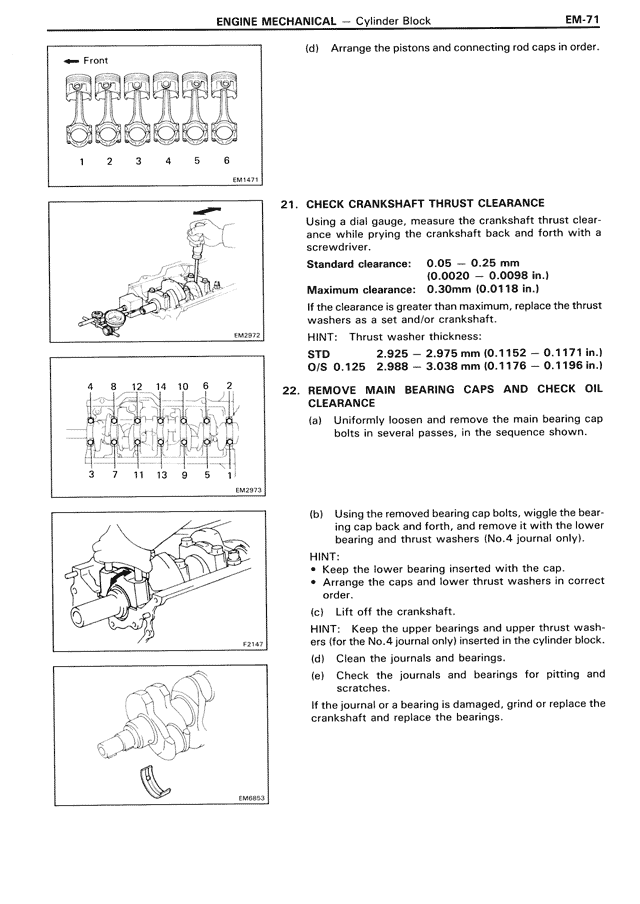

(d) Arrange the pistons and connecting rod caps in order.

21. CHECK CRANKSHAFT THRUST CLEARANCE

Using a dial gauge, measure the crankshaft thrust clearance while prying the crankshaft back and forth with a screwdriver.

Standard clearance: 0.05 — 0.25 mm

(0.0020 — 0.0098 in.)

Maximum clearance: 0.30mm (0.0118 in.)

If the clearance is greater than maximum, replace the thrust washers as a set and/or crankshaft.

HINT: Thrust washer thickness:

STD 2.925 — 2.975 mm (0.1152 — 0.1171 in.)

O/S 0.125 2.988 — 3.038 mm (0.1176 — 0.1196 in.)

22. REMOVE MAIN BEARING CAPS AND CHECK OIL CLEARANCE

(a) Uniformly loosen and remove the main bearing cap bolts in several passes, in the sequence shown.

[Diagram showing loosening sequence: 4 8 12 14 10 6 2 and 3 7 11 13 9 5 1]

(b) Using the removed main bearing cap bolts, wiggle the bearing cap back and forth, and remove it with the lower bearing and thrust washers (No.4 journal only).

HINT:

• Keep the lower bearing inserted with the cap.

• Arrange the caps and lower thrust washers in correct order.

(c) Lift off the crankshaft.

HINT: Keep the upper bearings and upper thrust washers (for the No.4 journal only) inserted in the cylinder block.

(d) Clean the journals and bearings.

(e) Check the journals and bearings for pitting and scratches.

If the journal or a bearing is damaged, grind or replace the crankshaft and replace the bearings.