ENGINE MECHANICAL — Cylinder Block EM-73

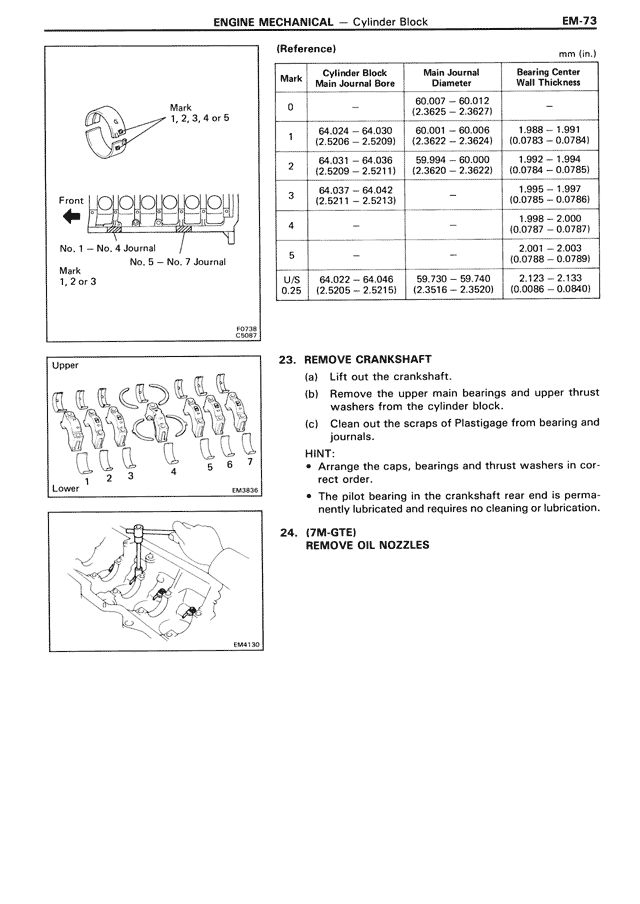

(Reference)

mm (in.)

Mark

1, 2, 3, 4 or 5

Front

← [DIAGRAM SHOWING CYLINDER JOURNALS]

No. 1 — No. 4 Journal

No. 5 — No. 7 Journal

Mark

1, 2 or 3

Mark Cylinder Block Main Journal Bearing Center

Main Journal Bore Diameter Wall Thickness

0 — 69.007 — 69.012 —

(2.5025 — 2.5027)

1 64.024 — 64.030 69.001 — 69.006 1.988 — 1.991

(2.5206 — 2.5209) (2.3622 — 2.3624) (0.0783 — 0.0784)

2 64.031 — 64.036 59.994 — 60.000 1.982 — 1.994

(2.5209 — 2.5211) (2.3620 — 2.3622) (0.0784 — 0.0786)

3 64.037 — 64.042 — 1.995 — 1.997

(2.5211 — 2.5213) (0.0785 — 0.0786)

4 — — 1.998 — 2.000

(0.0787 — 0.0787)

5 — — 2.001 — 2.003

(0.0788 — 0.0789)

U/S 64.022 — 64.046 59.730 — 59.740 2.023 — 2.025

0.25 (2.5205 — 2.5215) (2.3516 — 2.3520) (0.0796 — 0.0840)

EO738

C5661

[DIAGRAM SHOWING BEARING CAP POSITIONS]

Upper 1 2 3 4 5 6 7

Lower

EM3839

23. REMOVE CRANKSHAFT

(a) Lift out the crankshaft.

(b) Remove the upper main bearings and upper thrust

washers from the cylinder block.

(c) Clean out the scraps of Plastigage from bearing and

journals.

HINT:

• Arrange the caps, bearings and thrust washers in cor-

rect order.

• The pilot bearing in the crankshaft rear end is perma-

nently lubricated and requires no cleaning or lubrication.

24. (7M-GTE)

REMOVE OIL NOZZLES

[DIAGRAM SHOWING OIL NOZZLE REMOVAL]

EM4130