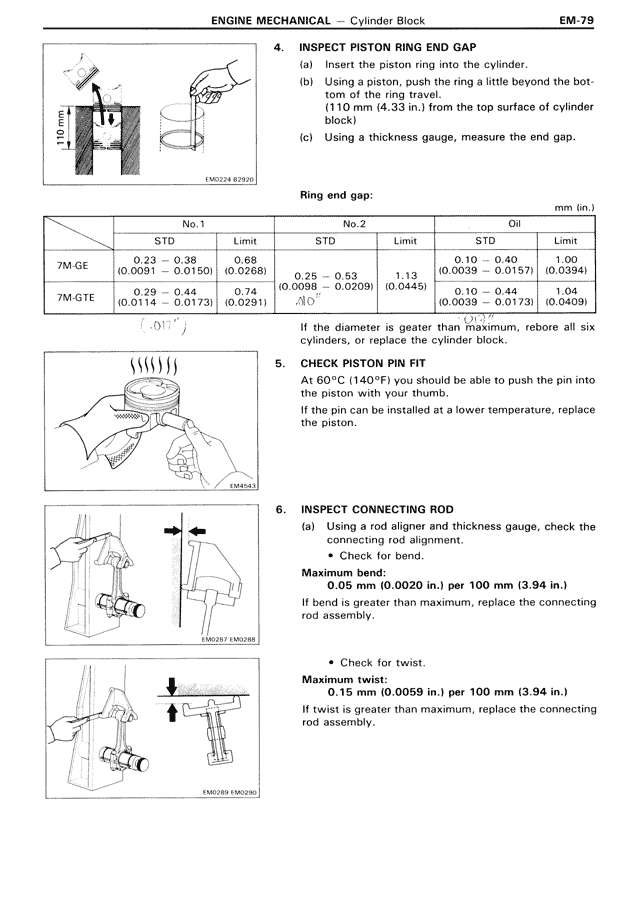

4. INSPECT PISTON RING END GAP

(a) Insert the piston ring into the cylinder.

(b) Using a piston, push the ring a little beyond the bottom of the ring travel.

(110 mm (4.33 in.) from the top surface of cylinder block)

(c) Using a thickness gauge, measure the end gap.

Ring end gap:

No.1 No.2 Oil

STD Limit STD Limit STD Limit

7M-GE 0.23 - 0.38 0.68 0.10 - 0.40 1.00

(0.0091 - 0.0150) (0.0268) 0.25 - 0.53 1.13 (0.0039 - 0.0157) (0.0394)

7M-GTE 0.29 - 0.44 0.74 (0.0098 - 0.0209) (0.0445)

(0.0114 - 0.0173) (0.0291) -Δo- 0.10 - 0.44 1.04

(0.0039 - 0.0173) (0.0409)

If the diameter is greater than maximum, rebore all six cylinders, or replace the cylinder block.

5. CHECK PISTON PIN FIT

At 60°C (140°F) you should be able to push the pin into the piston with your thumb.

If the pin can be installed at a lower temperature, replace the piston.

6. INSPECT CONNECTING ROD

(a) Using a rod aligner and thickness gauge, check the connecting rod alignment.

• Check for bend:

Maximum bend:

0.05 mm (0.0020 in.) per 100 mm (3.94 in.)

If bend is greater than maximum, replace the connecting rod assembly.

• Check for twist:

Maximum twist:

0.15 mm (0.0059 in.) per 100 mm (3.94 in.)

If twist is greater than maximum, replace the connecting rod assembly.