MAINTENANCE OPERATIONS

ENGINE

Cold Engine Operations

1. REPLACE TIMING BELT

(a) Remove the timing belt.

(See pages EM-22 to 25)

(b) Install the timing belt.

(See pages EM-28 to 31)

2. INSPECT DRIVE BELTS

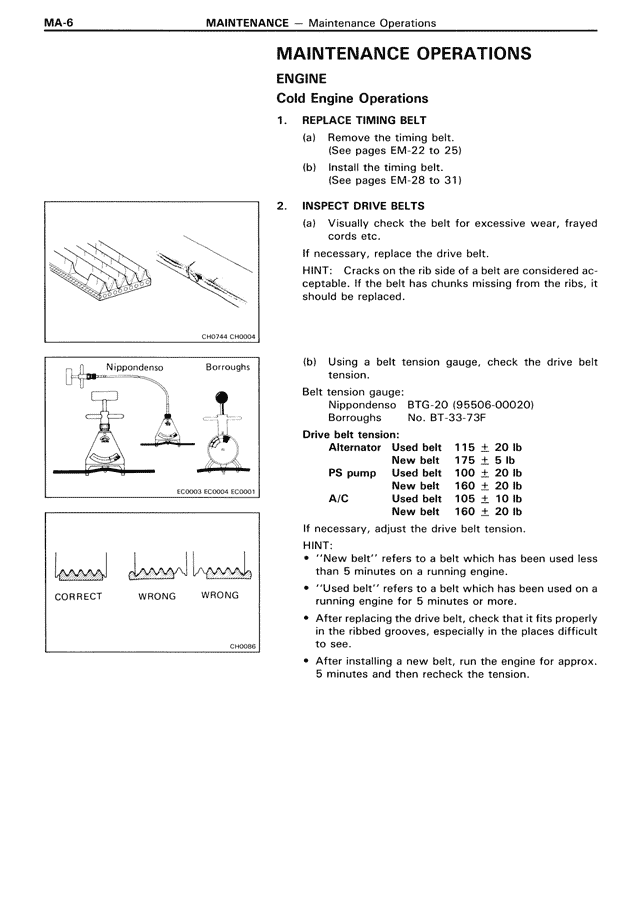

(a) Visually check the belt for excessive wear, frayed cords etc.

If necessary, replace the drive belt.

HINT: Cracks on the rib side of a belt are considered acceptable. If the belt has chunks missing from the ribs, it should be replaced.

(b) Using a belt tension gauge, check the drive belt tension.

Belt tension gauge:

Nippondenso BTG-20 (95506-00020)

Borroughs No. BT-33-73F

Drive belt tension:

Alternator Used belt 115 ± 20 lb

New belt 175 ± 5 lb

PS pump Used belt 115 ± 20 lb

New belt 160 ± 20 lb

A/C Used belt 105 ± 10 lb

New belt 160 ± 20 lb

If necessary, adjust the drive belt tension.

HINT:

• "New belt" refers to a belt which has been used less than 5 minutes on a running engine.

• "Used belt" refers to a belt which has been used on a running engine for 5 minutes or more.

• After replacing the drive belt, check that it fits properly in the ribbed grooves, especially in the places difficult to see.

• After installing a new belt, run the engine for approx. 5 minutes and then recheck the tension.