MANUAL TRANSMISSION — Component Parts (Output Shaft Assembly) MT-63

INSPECT OF OUTPUT SHAFT ASSEMBLY

1. MEASURE EACH GEAR THRUST CLEARANCE

(a) Using a feeler gauge, measure the thrust clearance of 1st gear and 3rd gear.

(b) Using a dial indicator, measure the thrust clearance of 2nd gear.

1st gear

Standard clearance: 0.10 — 0.45 mm

(0.0039 — 0.0177 in.)

Maximum clearance: 0.50 mm (0.0197in.)

2nd and 3rd gear

Standard clearance: 0.10 — 0.25 mm

(0.0039 — 0.0098 in.)

Maximum clearance: 0.30 mm (0.0118 in.)

2. CHECK OIL CLEARANCE OF EACH GEAR

Using a dial indicator, measure the oil clearance between the gear and shaft with the needle roller bearing installed.

1st gear

Standard clearance: 0.020 — 0.073 mm

(0.0008 — 0.0029 in.)

Maximum clearance: 0.16 mm (0.0063 in.)

2nd and 3rd gear

Standard clearance: 0.015 — 0.068 mm

(0.0006 — 0.0027 in.)

Maximum clearance: 0.16 mm (0.0063 in.)

If the clearance exceeds the limit, replace the gear, needle roller bearing or shaft.

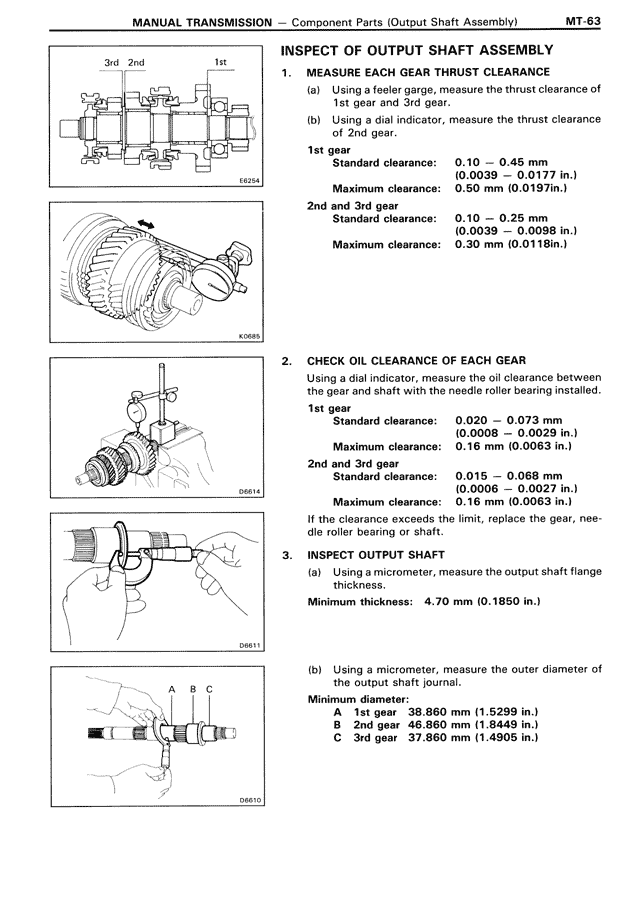

3. INSPECT OUTPUT SHAFT

(a) Using a micrometer, measure the output shaft flange thickness.

Minimum thickness: 4.70 mm (0.1850 in.)

(b) Using a micrometer, measure the outer diameter of the output shaft journal.

Minimum diameter:

A 1st gear 38.860 mm (1.5299 in.)

B 2nd gear 46.860 mm (1.8449 in.)

C 3rd gear 37.860 mm (1.4905 in.)