ASSEMBLY OF DIFFERENTIAL CARRIER

(See page RA-23)

1. ASSEMBLE DIFFERENTIAL CASE

(Conventional type: See page RA-44, 47)

(LSD type: See page RA-63)

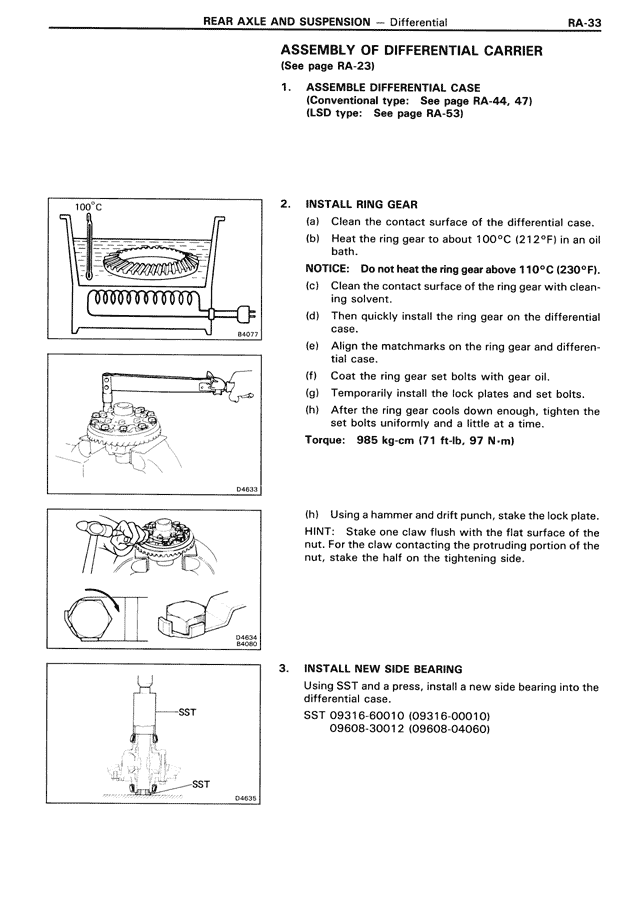

2. INSTALL RING GEAR

(a) Clean the contact surface of the differential case.

(b) Heat the ring gear to about 100°C (212°F) in an oil bath.

NOTICE: Do not heat the ring gear above 110°C (230°F).

(c) Clean the contact surface of the ring gear with cleaning solvent.

(d) Then quickly install the ring gear on the differential case.

(e) Align the matchmarks on the ring gear and differential case.

(f) Coat the ring gear set bolts with gear oil.

(g) Temporarily install the lock plates and set bolts.

(h) After the ring gear cools down enough, tighten the set bolts uniformly and a little at a time.

Torque: 985 kg-cm (71 ft-lb, 97 N-m)

(h) Using a hammer and drift punch, stake the lock plate.

HINT: Stake one claw flush with the flat surface of the nut. For the claw contacting the protruding portion of the nut, stake the half on the tightening side.

3. INSTALL NEW SIDE BEARING

Using SST and a press, install a new side bearing into the differential case.

SST 09316-60010 (09316-00010)

09608-30012 (09608-04060)