Brush Holder

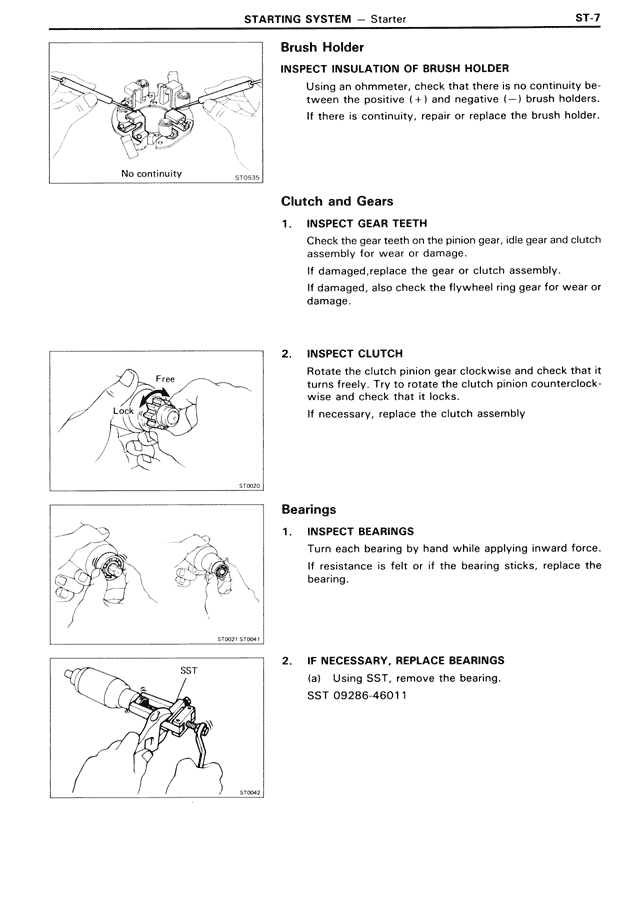

INSPECT INSULATION OF BRUSH HOLDER

Using an ohmmeter, check that there is no continuity between the positive (+) and negative (-) brush holders.

If there is continuity, repair or replace the brush holder.

No continuity

Clutch and Gears

1. INSPECT GEAR TEETH

Check the gear teeth on the pinion gear, idle gear and clutch assembly for wear or damage.

If damaged,replace the gear or clutch assembly.

If damaged, also check the flywheel ring gear for wear or damage.

2. INSPECT CLUTCH

Rotate the clutch pinion gear clockwise and check that it turns freely. Try to rotate the clutch pinion counterclockwise and check that it locks.

If necessary, replace the clutch assembly

Free

Lock

Bearings

1. INSPECT BEARINGS

Turn each bearing by hand while applying inward force.

If resistance is felt or if the bearing sticks, replace the bearing.

2. IF NECESSARY, REPLACE BEARINGS

(a) Using SST, remove the bearing.

SST 09286-46011

SST