Discharging of Refrigeration System

1. CONNECT MANIFOLD GAUGE SET TO COMPRESSOR

2. PLACE FREE END OF CENTER HOSE IN A SHOP TOWEL

3. DISCHARGE SYSTEM

(a) Slowly open the high pressure hand valve to adjust the refrigerant flow. Do not open valve very much.

CAUTION: If refrigerant is allowed to escape too fast, compressor oil will be drawn out of the system.

(b) Check the shop towel to make sure no oil is being discharged.

If oil is present, partially close the hand valve.

(c) After the manifold gauge reading drops below 3.5 kg/cm² (50 psi, 343 kPa), slowly open the low pressure valve.

(d) As the system pressure drops, gradually open both high and low valves until both gauges read 0 kg/cm² (0 psi, 0 kPa).

Evacuating and Charging of Refrigeration System

NOTE:

• Whenever the air conditioning system has been exposed to the atmosphere, it must be evacuated.

• After installation of a component, the system should be evacuated for approximately 15 minutes. A component in service that has been opened for repair should be evacuated for 30 minutes.

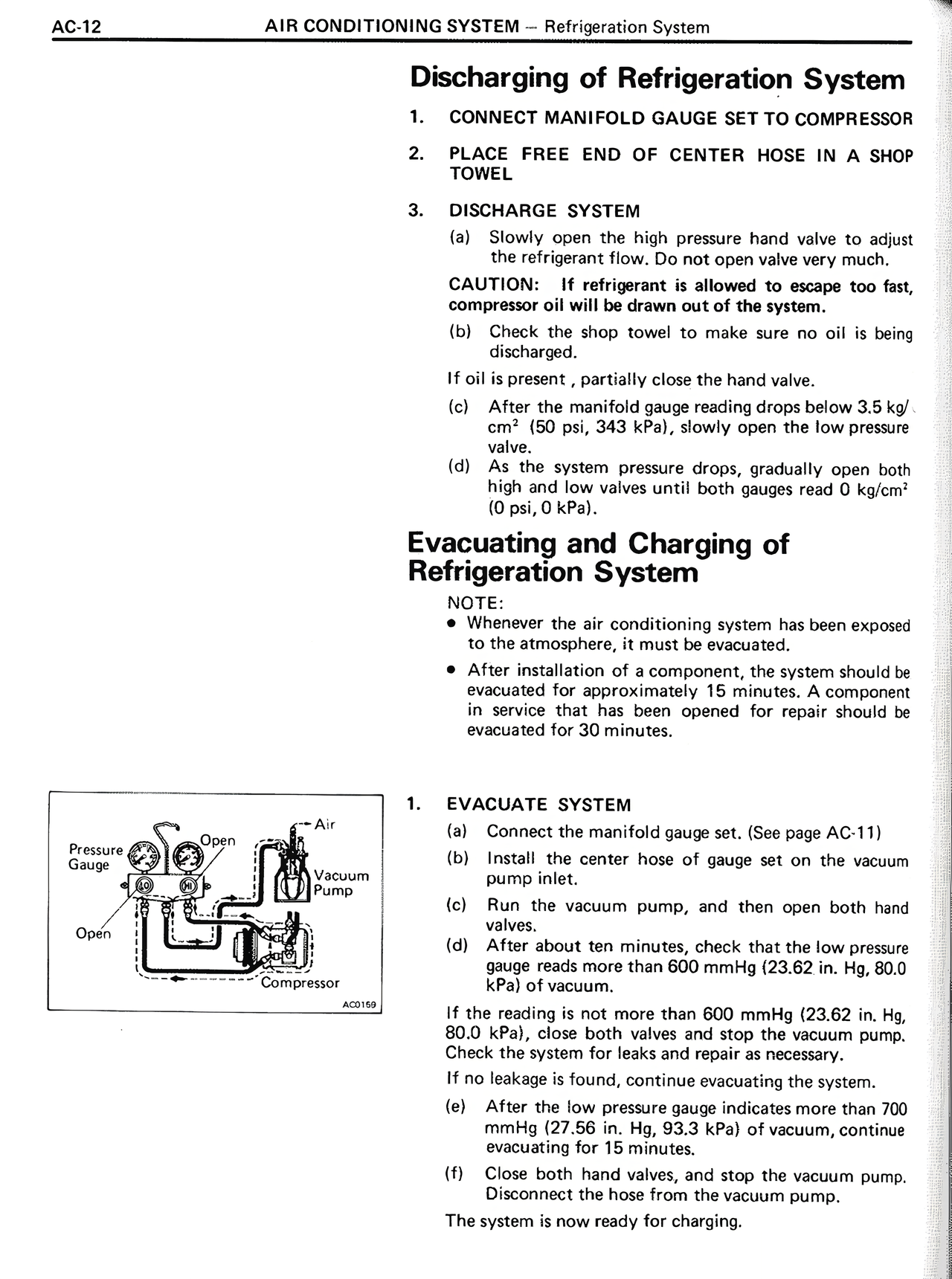

1. EVACUATE SYSTEM

(a) Connect the manifold gauge set. (See page AC-11)

(b) Install the center hose of gauge set on the vacuum pump inlet.

(c) Run the vacuum pump, and then open both hand valves.

(d) After about ten minutes, check that the low pressure gauge reads more than 600 mmHg (23.62 in. Hg, 80.0 kPa) of vacuum.

If the reading is not more than 600 mmHg (23.62 in. Hg, 80.0 kPa), close both valves and stop the vacuum pump. Check the system for leaks and repair as necessary.

If no leakage is found, continue evacuating the system.

(e) After the low pressure gauge indicates more than 700 mmHg (27.56 in. Hg, 93.3 kPa) of vacuum, continue evacuating for 15 minutes.

(f) Close both hand valves, and stop the vacuum pump. Disconnect the hose from the vacuum pump.

The system is now ready for charging.