4. INSTALL PRESSURE PLATE

(a) Adjust the clearance between the pressure plate and rotor by placing shims on the compressor shaft.

Standard clearance: 0.4 - 0.7 mm (0.016 - 0.028 in.)

If the clearance is not within tolerance, add or reduce the number of shims to obtain the standard clearance.

(b) Using SST and a torque wrench, install the shaft nut.

SST 07110-77011

Torque: 165 kg·cm (12 ft·lb, 16 N·m)

PERFORMANCE TEST OF COMPRESSOR

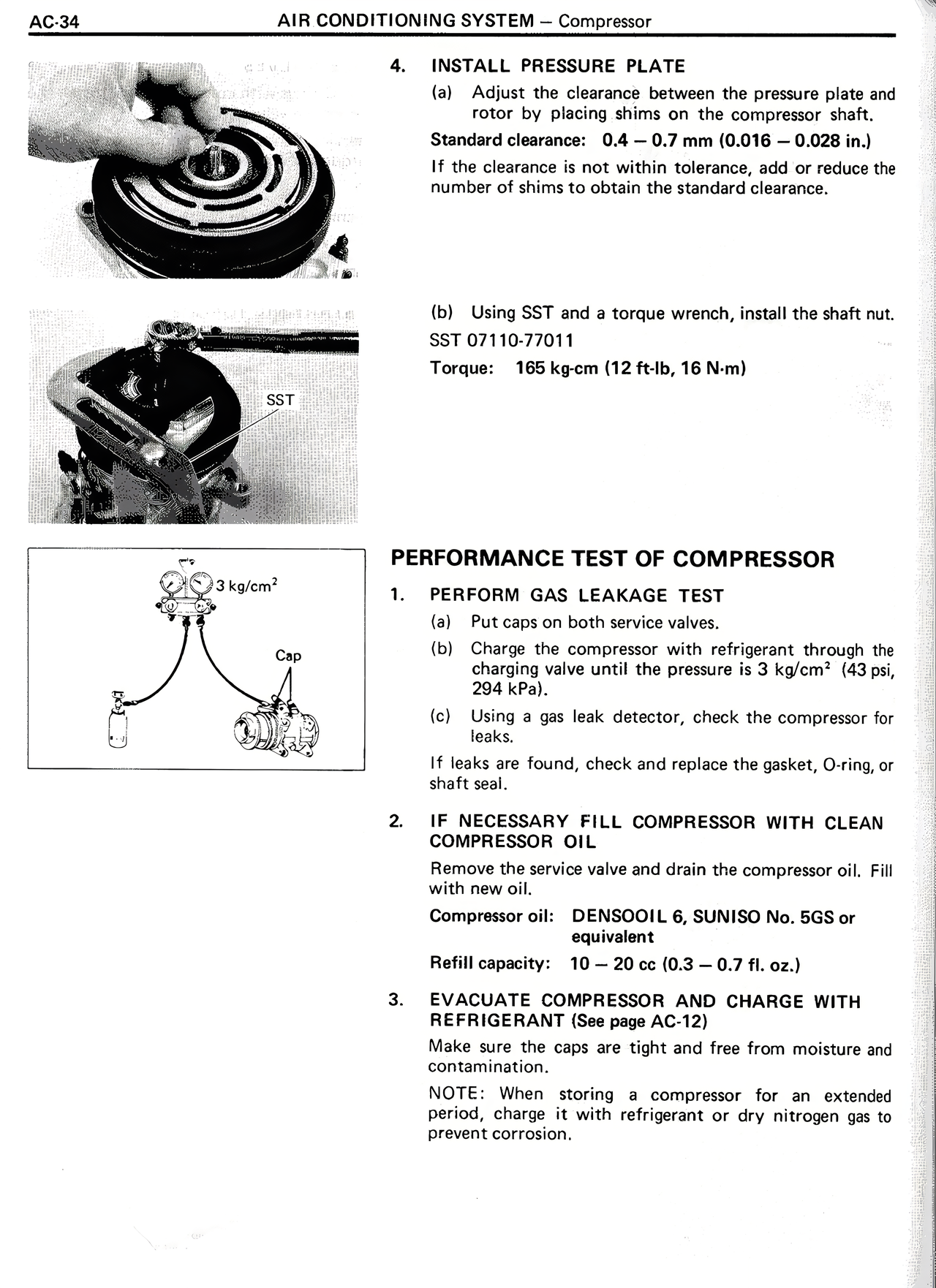

1. PERFORM GAS LEAKAGE TEST

(a) Put caps on both service valves.

(b) Charge the compressor with refrigerant through the charging valve until the pressure is 3 kg/cm² (43 psi, 294 kPa).

(c) Using a gas leak detector, check the compressor for leaks.

If leaks are found, check and replace the gasket, O-ring, or shaft seal.

2. IF NECESSARY FILL COMPRESSOR WITH CLEAN COMPRESSOR OIL

Remove the service valve and drain the compressor oil. Fill with new oil.

Compressor oil: DENSOIL 6, SUNISO No. 5GS or equivalent

Refill capacity: 10 - 20 cc (0.3 - 0.7 fl. oz.)

3. EVACUATE COMPRESSOR AND CHARGE WITH REFRIGERANT (See page AC-12)

Make sure the caps are tight and free from moisture and contamination.

NOTE: When storing a compressor for an extended period, charge it with refrigerant or dry nitrogen gas to prevent corrosion.