INSTALLATION OF TRANSMISSION

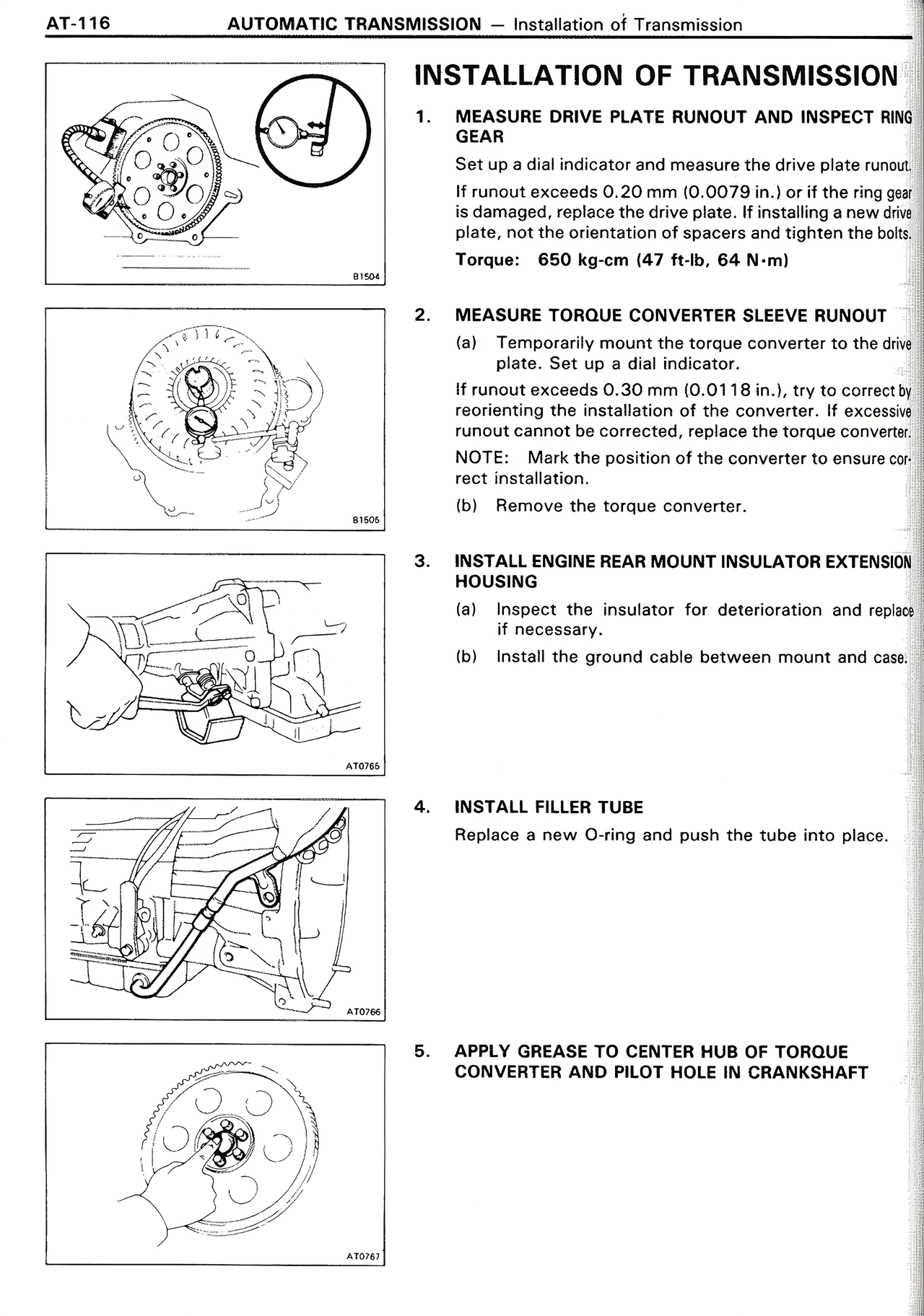

1. MEASURE DRIVE PLATE RUNOUT AND INSPECT RING GEAR

Set up a dial indicator and measure the drive plate runout.

If runout exceeds 0.20 mm (0.0079 in.) or if the ring gear is damaged, replace the drive plate. If installing a new drive plate, not the orientation of spacers and tighten the bolts.

Torque: 650 kg-cm (47 ft-lb, 64 N-m)

2. MEASURE TORQUE CONVERTER SLEEVE RUNOUT

(a) Temporarily mount the torque converter to the drive plate. Set up a dial indicator.

If runout exceeds 0.30 mm (0.0118 in.), try to correct by reorienting the installation of the converter. If excessive runout cannot be corrected, replace the torque converter.

NOTE: Mark the position of the converter to ensure correct installation.

(b) Remove the torque converter.

3. INSTALL ENGINE REAR MOUNT INSULATOR EXTENSION HOUSING

(a) Inspect the insulator for deterioration and replace if necessary.

(b) Install the ground cable between mount and case.

4. INSTALL FILLER TUBE

Replace a new O-ring and push the tube into place.

5. APPLY GREASE TO CENTER HUB OF TORQUE CONVERTER AND PILOT HOLE IN CRANKSHAFT