2. INSPECT DISC, PLATE AND FLANGE

Check that the sliding surface of disc is not worn or burnt.

If the disc is worn or burnt, replace all discs.

Then check that the sliding surfaces of plate and flange

are not worn or burnt.

If necessary, replace them.

NOTE: Do not allow the discs to dry out.

Prepare new discs by soaking them at least two hours in

ATF.

ASSEMBLY OF REAR CLUTCH

(See page AT-67)

1. INSTALL NEW O-RINGS ON PISTON

2. INSTALL REAR CLUTCH PISTON IN DRUM

Press rear clutch piston into drum with the cup side up,

being careful not to damage the O-rings.

3. INSTALL EIGHTEEN PISTON RETURN SPRINGS AND SET

RETAINER WITH SNAP RING IN PLACE

4. COMPRESS RETURN SPRINGS AND INSTALL SNAP RING

IN GROOVE

(a) Place SST on the spring retainer, and compress the

springs on shop press.

SST 09350-20013 (09369-20040)

(b) Install the snap ring with snap ring pliers.

5. INSTALL DISCS, PLATES AND FLANGE

With low-pressure compressed air, blow all excess ATF

from discs.

CAUTION: High-pressure air will damage the discs.

Install in order: Plate-disc-plate-disc-plate-disc-flange (flat

end down)

6. INSTALL SNAP RING

Check that the snap ring ends are not aligned with one of

the cutouts.

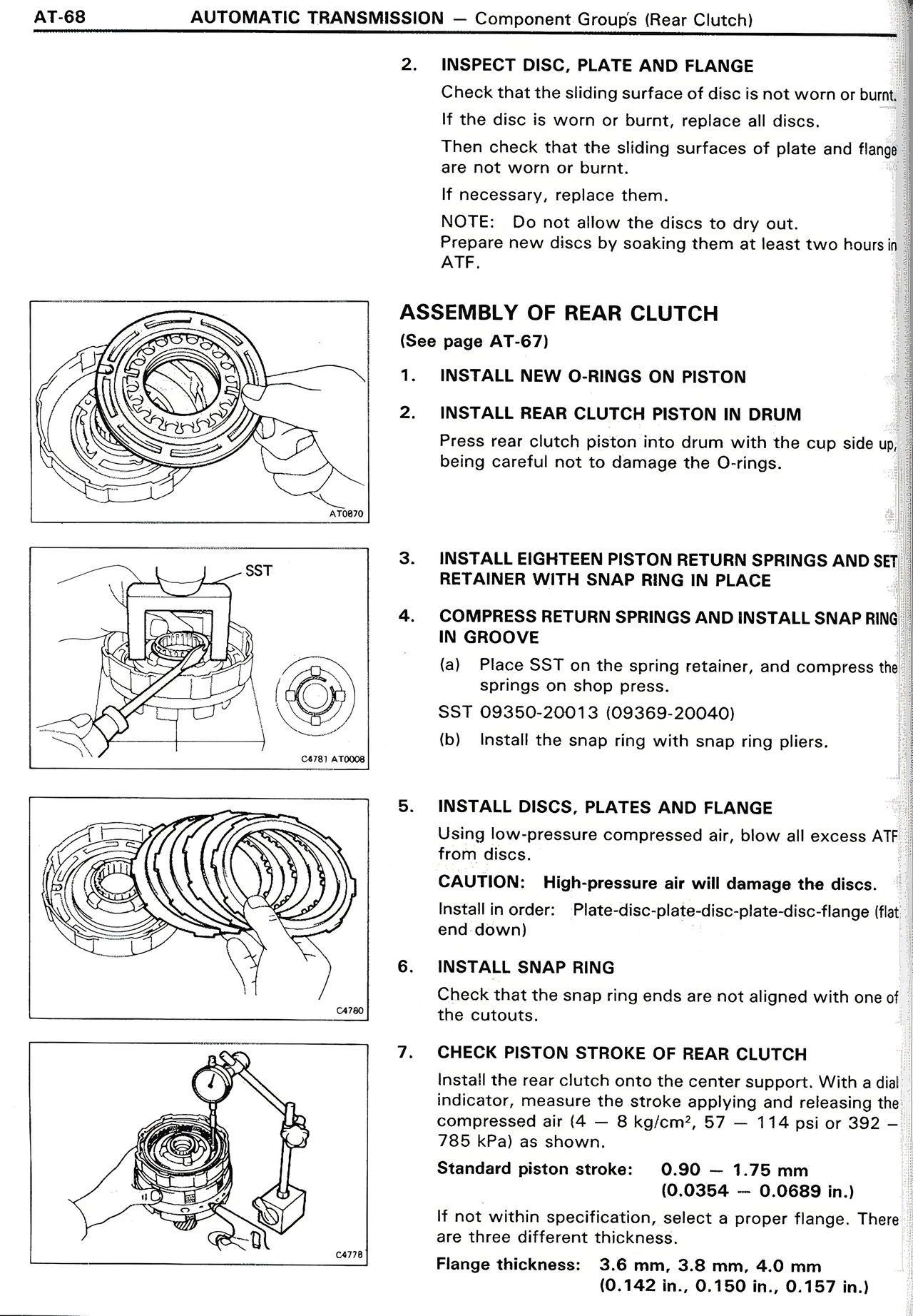

7. CHECK PISTON STROKE OF REAR CLUTCH

Install the rear clutch onto the center support. With a dial

indicator, measure the stroke applying and releasing the

compressed air (4 — 8 kgf/cm², 57 — 114 psi or 392 —

785 kPa) as shown.

Standard piston stroke: 0.90 — 1.75 mm

(0.0354 — 0.0689 in.)

If not within specification, select a proper flange. There

are three different thickness.

Flange thickness: 3.6 mm, 3.8 mm, 4.0 mm

(0.142 in., 0.150 in., 0.157 in.)