EM-28 ENGINE MECHANICAL — Cylinder Head

(d) Hand lap the valve and valve seat together with abrasive compound.

(e) Clean the valve and valve seat after hand-lapping.

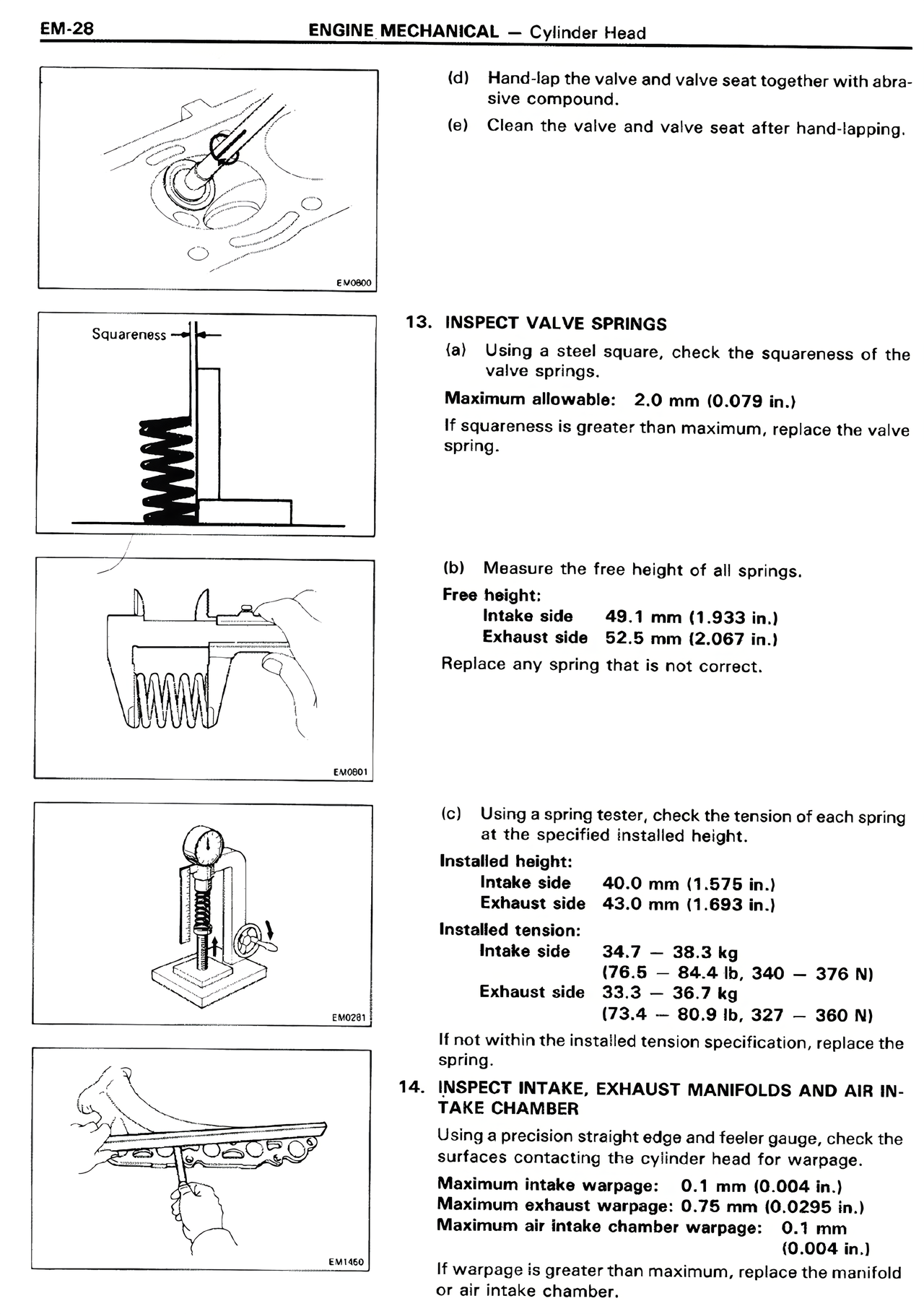

13. INSPECT VALVE SPRINGS

(a) Using a steel square, check the squareness of the valve springs.

Maximum: 2.0 mm (0.079 in.)

If squareness is greater than maximum, replace the valve spring.

(b) Measure the free height of all springs.

Free height:

Intake side 49.1 mm (1.933 in.)

Exhaust side 52.5 mm (2.067 in.)

Replace any spring that is not correct.

(c) Using a spring tester, check the tension of each spring at the specified installed height.

Installed height:

Intake side 40.0 mm (1.575 in.)

Exhaust side 43.0 mm (1.693 in.)

Installed tension:

Intake side 34.7 — 38.3 kg

(76.5 — 84.4 lb, 340 — 376 N)

Exhaust side 33.3 — 36.7 kg

(73.4 — 80.9 lb, 327 — 360 N)

If not within the installed tension specification, replace the spring.

14. INSPECT INTAKE, EXHAUST MANIFOLDS AND AIR IN-TAKE CHAMBER

Using a precision straight edge and feeler gauge, check the surfaces contacting the cylinder head for warpage.

Maximum intake warpage: 0.1 mm (0.004 in.)

Maximum exhaust warpage: 0.75 mm (0.0295 in.)

Maximum air intake chamber warpage: 0.1 mm

(0.004 in.)

If warpage is greater than maximum, replace the manifold or air intake chamber.