(b) Check the valve head margin.

Minimum margin: Intake 0.5 mm (0.020 in.)

Exhaust 1.0 mm (0.039 in.)

If the valve head margin is less than specified, replace the valve.

(c) Check the surface of the valve stem tip for wear.

Standard overall length:

Intake 107.5 mm (4.232 in.)

Exhaust 109.7 mm (4.319 in.)

If the valve stem tip is worn, resurface the tip with a grinder or replace the valve.

CAUTION: Do not grind more than 0.5 mm (0.020 in.).

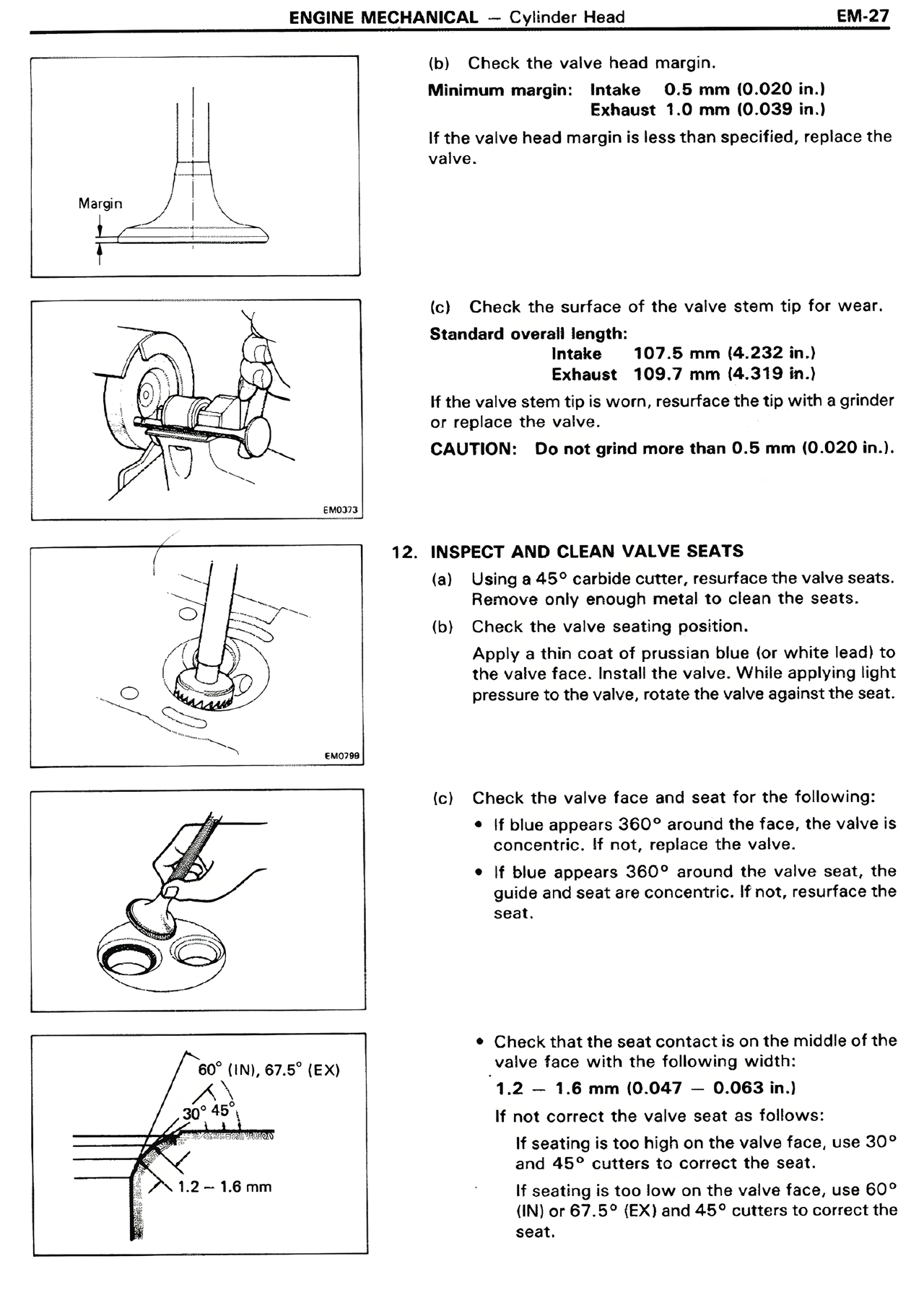

12. INSPECT AND CLEAN VALVE SEATS

(a) Using a 45° carbide cutter, resurface the valve seats. Remove only enough metal to clean the seats.

(b) Check the valve seating position.

Apply a thin coat of prussian blue (or white lead) to the valve face. Install the valve. While applying light pressure to the valve, rotate the valve against the seat.

(c) Check the valve face and seat for the following:

• If blue appears 360° around the face, the valve is concentric. If not, replace the valve.

• If blue appears 360° around the valve seat, the guide and seat are concentric. If not, resurface the seat.

• Check that the seat contact is on the middle of the valve face with the following width:

1.2 — 1.6 mm (0.047 — 0.063 in.)

If not correct the valve seat as follows:

If seating is too high on the valve face, use 30° and 45° cutters to correct the seat.

If seating is too low on the valve face, use 60° (IN) or 67.5° (EX) and 45° cutters to correct the seat.