EM-44 ENGINE MECHANICAL — Cylinder Block

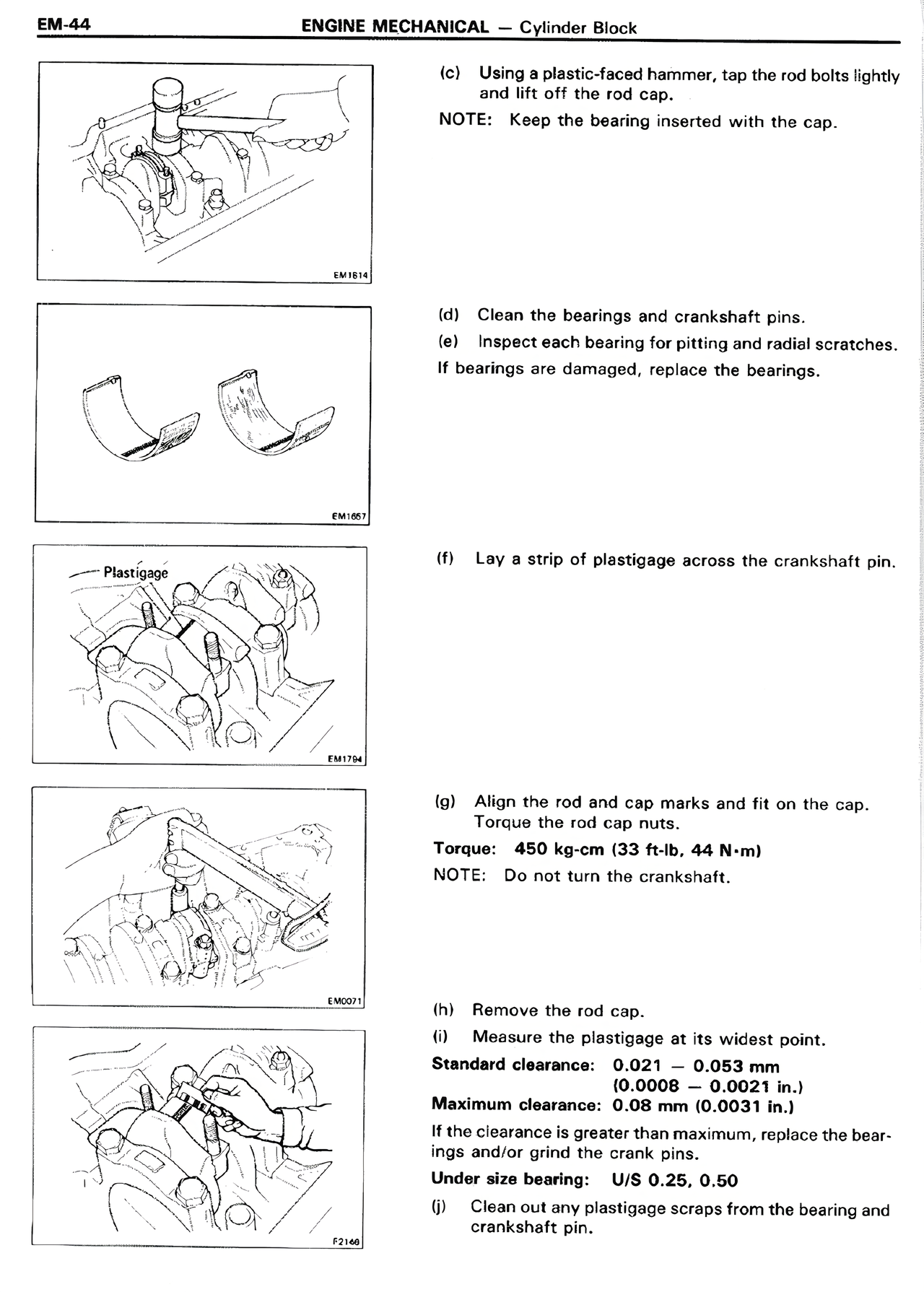

(c) Using a plastic-faced hammer, tap the rod bolts lightly and lift off the rod cap.

NOTE: Keep the bearing inserted with the cap.

(d) Clean the bearings and crankshaft pins.

(e) Inspect each bearing for pitting and radial scratches. If bearings are damaged, replace the bearings.

(f) Lay a strip of plastigage across the crankshaft pin.

(g) Align the rod and cap marks and fit on the cap. Torque the rod cap nuts.

Torque: 450 kg-cm (33 ft-lb, 44 N-m)

NOTE: Do not turn the crankshaft.

(h) Remove the rod cap.

(i) Measure the plastigage at its widest point.

Standard clearance: 0.021 - 0.053 mm (0.0008 - 0.0021 in.)

Maximum clearance: 0.08 mm (0.0031 in.)

If the clearance is greater than maximum, replace the bearings and/or grind the crank pins.

Under size bearing: U/S 0.25, 0.50

(j) Clean out any plastigage scraps from the bearing and crankshaft pin.