ENGINE MECHANICAL — Cylinder Block EM-47

(h) Install the main bearing caps. Torque the cap bolts.

Torque: 1,040 kg-cm (75 ft-lb, 102 N·m)

NOTE: Do not turn crankshaft.

(i) Remove the main bearing caps.

(j) Measure the plastigauge at its widest point.

Standard clearance: 0.034 — 0.066 mm

(0.0013 — 0.0023 in.)

Maximum clearance: 0.08 mm (0.0031 in.)

If the clearance is greater than maximum, replace the bearings and/or grind the main journals.

Undersized bearing: U/S 0.25, 0.50

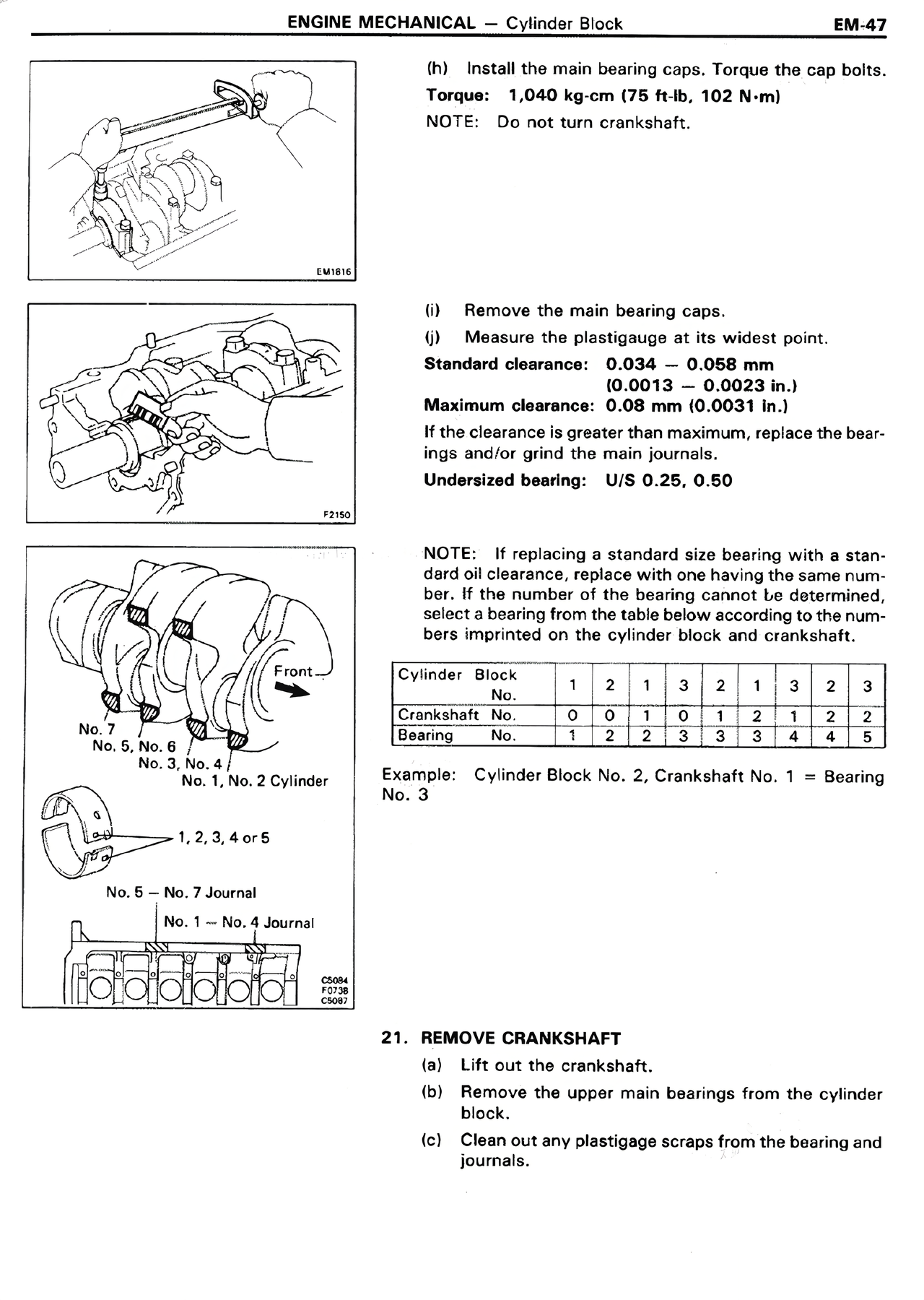

NOTE: If replacing a standard size bearing with a standard oil clearance, replace with one having the same numbers stamped on it. If the number of the bearing cannot be determined, select a bearing from the table below according to the numbers imprinted on the cylinder block and crankshaft.

Cylinder Block 1 2 1 2 3 1 3 2 3

No.

Crankshaft No. 0 0 1 0 1 2 1 2 2

Bearing No. 1 2 2 3 3 3 4 4 5

Example: Cylinder Block No. 2, Crankshaft No. 1 = Bearing No. 3

No. 7 — No. 6

No. 5, No. 6

No. 3, 4

No. 1, No. 2 Cylinder

1, 2, 3, 4 or 5

No. 6 — No. 7 Journal

No. 1 — No. 4 Journal

21. REMOVE CRANKSHAFT

(a) Lift out the crankshaft.

(b) Remove the upper main bearings from the cylinder

block.

(c) Clean out any plastigage scraps from the bearing and

journals.