INSPECTION OF CYLINDER BLOCK

1. REMOVE GASKET MATERIAL

Using a gasket scraper, remove all gasket material from the cylinder block surfaces.

2. CLEAN CYLINDER BLOCK

Using a soft brush and solvent, clean the block.

3. INSPECT CYLINDERS

Visually inspect cylinders for vertical scratches. If deep scratches are present, rebore all six cylinders. (See page EM-50)

4. INSPECT CYLINDER BLOCK WARPAGE

Warpage: Limit 0.05 mm (0.0020 in.)

If warpage is greater than the specified value, replace the cylinder block.

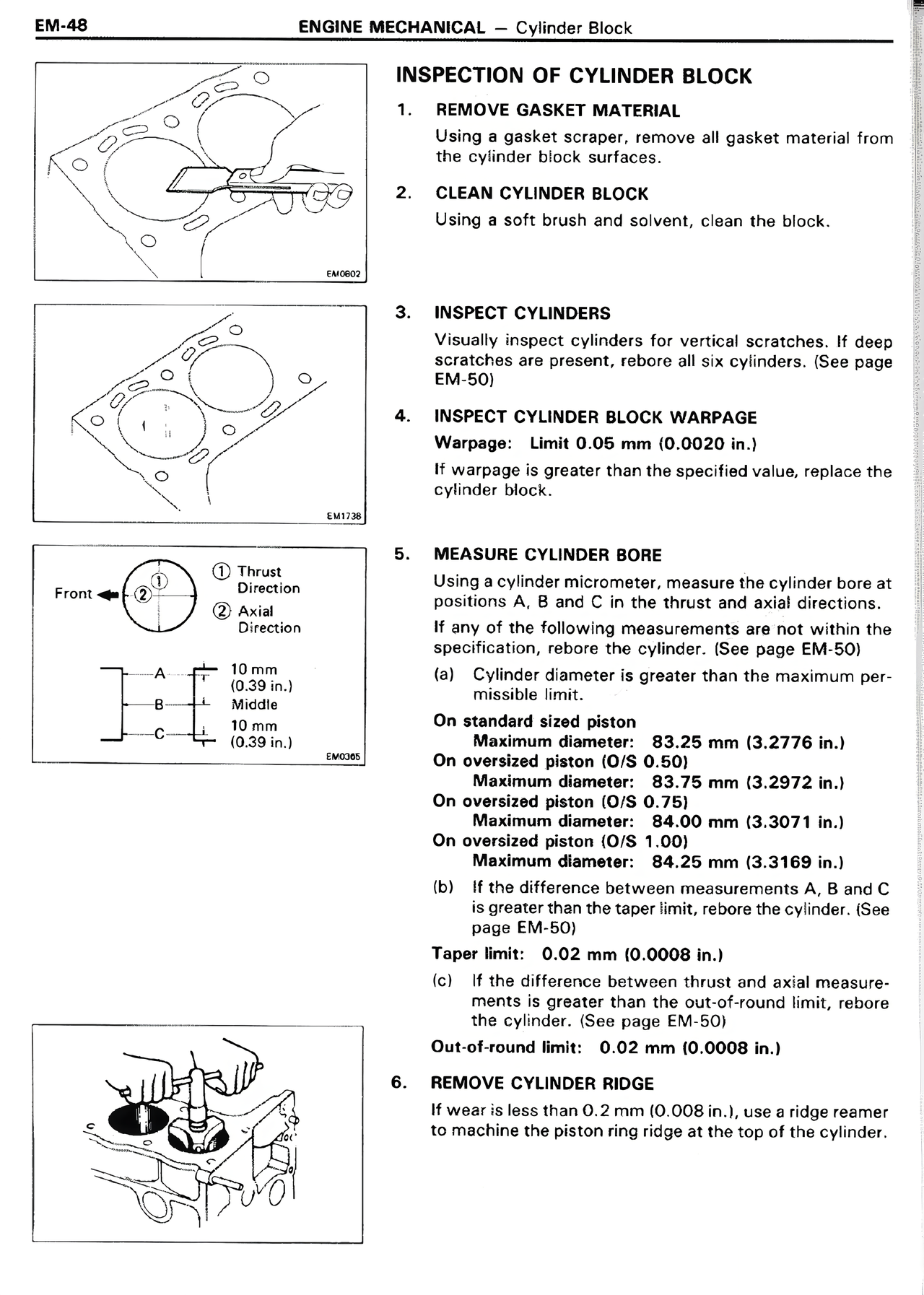

5. MEASURE CYLINDER BORE

Using a cylinder micrometer, measure the cylinder bore at positions A, B and C in the thrust and axial directions.

If any of the following measurements are not within the specification, rebore the cylinder. (See page EM-50)

(a) Cylinder diameter is greater than the maximum permissible limit.

On standard sized piston

Maximum diameter: 83.25 mm (3.2776 in.)

On oversized piston (O/S 0.50)

Maximum diameter: 83.75 mm (3.2972 in.)

On oversized piston (O/S 0.75)

Maximum diameter: 84.00 mm (3.3071 in.)

On oversized piston (O/S 1.00)

Maximum diameter: 84.25 mm (3.3169 in.)

(b) If the difference between measurements A, B and C is greater than the taper limit, rebore the cylinder. (See page EM-50)

Taper limit: 0.02 mm (0.0008 in.)

(c) If the difference between thrust and axial measurements is greater than the out-of-round limit, rebore the cylinder. (See page EM-50)

Out-of-round limit: 0.02 mm (0.0008 in.)

6. REMOVE CYLINDER RIDGE

If wear is less than 0.2 mm (0.008 in.), use a ridge reamer to machine the piston ring ridge at the top of the cylinder.

Front

① Thrust Direction

② Axial Direction

A 10 mm (0.39 in.)

Middle

B

C 10 mm (0.39 in.)

EM0602

EM1788

EM0498