EM-50

ENGINE MECHANICAL — Cylinder Block

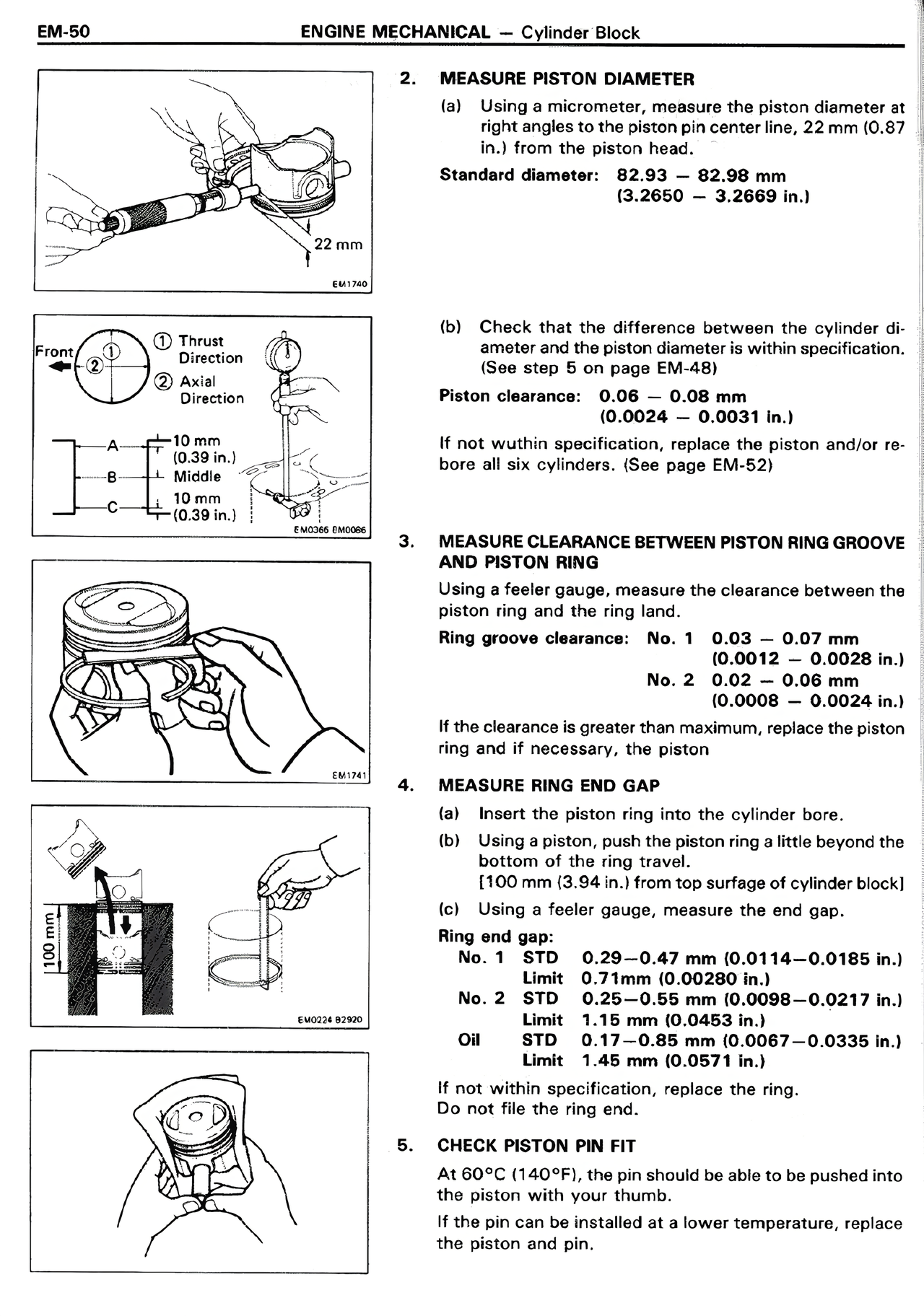

2. MEASURE PISTON DIAMETER

(a) Using a micrometer, measure the piston diameter at right angles to the piston pin center line, 22 mm (0.87 in.) from the piston head.

Standard diameter: 82.93 — 82.98 mm

(3.2650 — 3.2669 in.)

(b) Check that the difference between the cylinder diameter and the piston diameter is within specification.

(See step 5 on page EM-48)

Piston clearance: 0.06 — 0.08 mm

(0.0024 — 0.0031 in.)

If not within specification, replace the piston and/or rebore all six cylinders. (See page EM-52)

3. MEASURE CLEARANCE BETWEEN PISTON RING GROOVE AND PISTON RING

Using a feeler gauge, measure the clearance between the piston ring and the ring land.

Ring groove clearance: No. 1 0.03 — 0.07 mm

(0.0012 — 0.0028 in.)

No. 2 0.02 — 0.06 mm

(0.0008 — 0.0024 in.)

If the clearance is greater than maximum, replace the piston ring and if necessary, the piston

4. MEASURE RING END GAP

(a) Insert the piston ring into the cylinder bore.

(b) Using a piston, push the piston ring a little beyond the bottom of the ring travel.

(100 mm (3.94 in.) from top surface of cylinder block)

(c) Using a feeler gauge, measure the end gap.

Ring end gap:

No. 1 STD 0.29—0.47 mm (0.0114—0.0185 in.)

Limit 0.71mm (0.0280 in.)

No. 2 STD 0.25—0.55 mm (0.0098—0.0217 in.)

Limit 1.15 mm (0.0453 in.)

Oil STD 0.17—0.85 mm (0.0067—0.0335 in.)

Limit 1.45 mm (0.0571 in.)

If not within specification, replace the ring.

Do not file the ring end.

5. CHECK PISTON PIN FIT

At 60°C (140°F), the pin should be able to be pushed into the piston with your thumb.

If the pin can be installed at a lower temperature, replace the piston and pin.