EM-52 ENGINE MECHANICAL — Cylinder Block

[DIAGRAM: Illustration showing honing process]

EM003

[TABLE: Bushing sizes]

Size Outside diameter

mm (in.)

O/S 0.50 83.43 - 83.48

(3.2846 - 3.2866)

O/S 0.75 83.68 - 83.73

(3.2945 - 3.2965)

O/S 1.00 83.93 - 83.98

(3.3043 - 3.3063)

3. HONE NEW BUSHING AND CHECK PIN FIT IN CONNECTING ROD

(a) Hone the new bushing and check that the oil clearance is within the standard specification.

Standard oil clearance: 0.005 - 0.011 mm

(0.0002 - 0.0004 in.)

(b) Check the pin fit at normal room temperature.

Coat the pin with engine oil and push the pin into the rod with thumb pressure.

BORING OF CYLINDERS

1. SELECT OVERSIZE PISTON

O/S pistons with pins are available in the sizes listed. Replace pistons in matched sets. Take the largest bore measured and select the oversized piston for that bore. Bore all cylinders for the oversized piston selected.

[DIAGRAM: Illustration showing measurement at 22mm from piston head]

EM1262

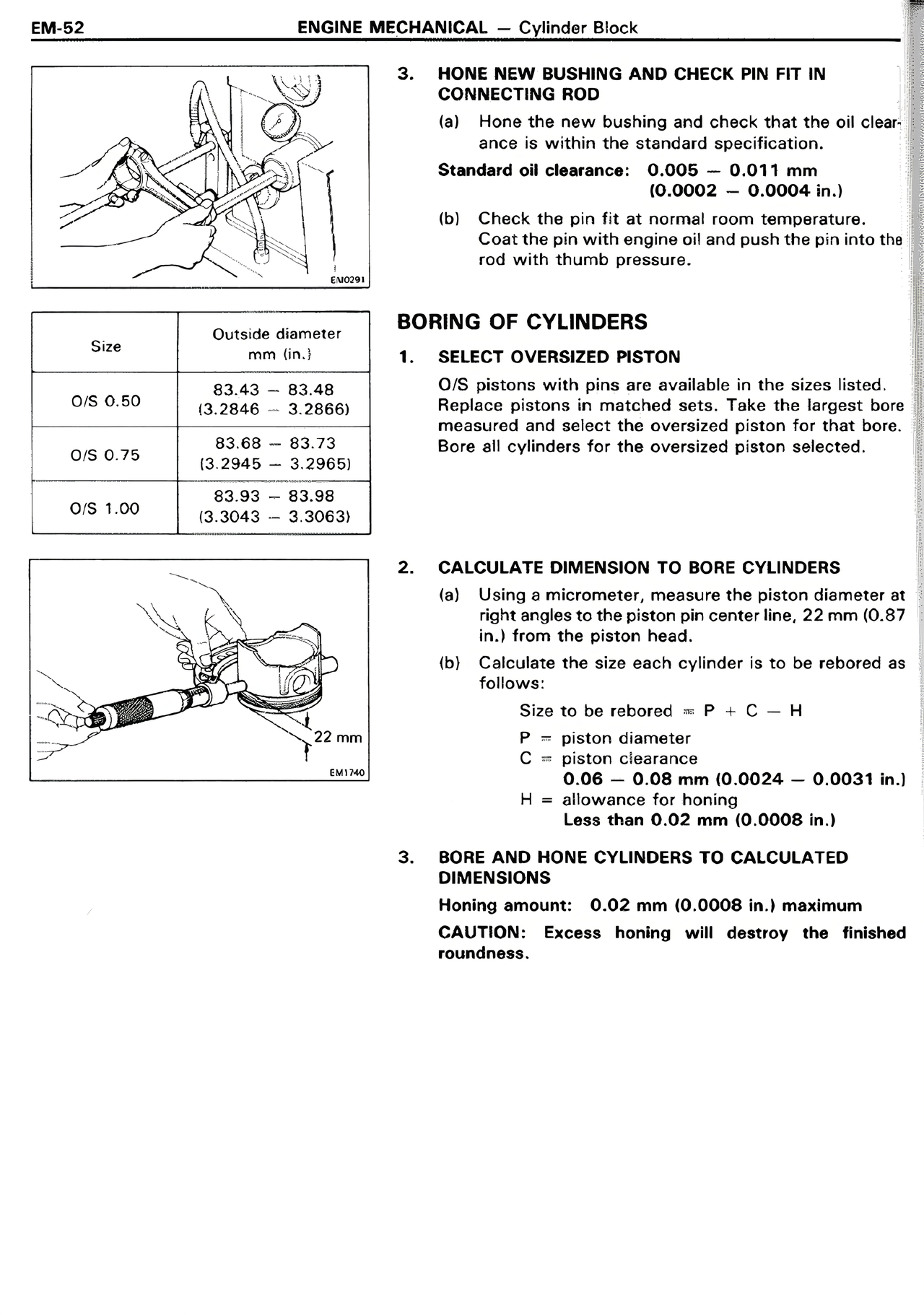

2. CALCULATE DIMENSION TO BORE CYLINDERS

(a) Using a micrometer, measure the piston diameter at right angles to the piston pin center line, 22 mm (0.87 in.) from the piston head.

(b) Calculate the size each cylinder is to be rebored as follows:

Size to be rebored = P + C - H

P = piston diameter

C = piston clearance

0.06 - 0.08 mm (0.0024 - 0.0031 in.)

H = allowance for honing

Less than 0.02 mm (0.0008 in.)

3. BORE AND HONE CYLINDERS TO CALCULATED DIMENSIONS

Honing amount: 0.02 mm (0.0008 in.) maximum

CAUTION: Excess honing will destroy the finished roundness.