5. INSTALL ROD BEARING CAPS

(a) Match the numbered cap with the numbered rod.

(b) Align the marks punched on the rod and cap and tighten the cap nuts to specified torque alternately in two or three passes.

Torque: 450 kg-cm (33 ft-lb, 44 N·m)

(c) After tightening the caps, check that the crankshaft rotates smoothly.

6. MEASURE ROD THRUST CLEARANCE

(See step 16 on page EM-43)

7. INSTALL OIL PUMP ASSEMBLY

(a) Clean the oil pump.

(b) Install the oil pump and holding bolt.

Torque the bolt.

Torque: 220 kg-cm (16 ft-lb, 22 N·m)

(c) Install the oil pipe with gasket, lock washer and union bolt. Tighten the oil pipe nut and bolt.

Torque: 350 kg-cm (25 ft-lb, 34 N·m)

8. INSTALL OIL PUMP DRIVE SHAFT

While turning the drive shaft, slowly insert so as not to damage the drive shaft bearing.

Torque the bolt.

Torque: 130 kg-cm (9 ft-lb, 13 N·m)

9. INSTALL REAR OIL SEAL RETAINER

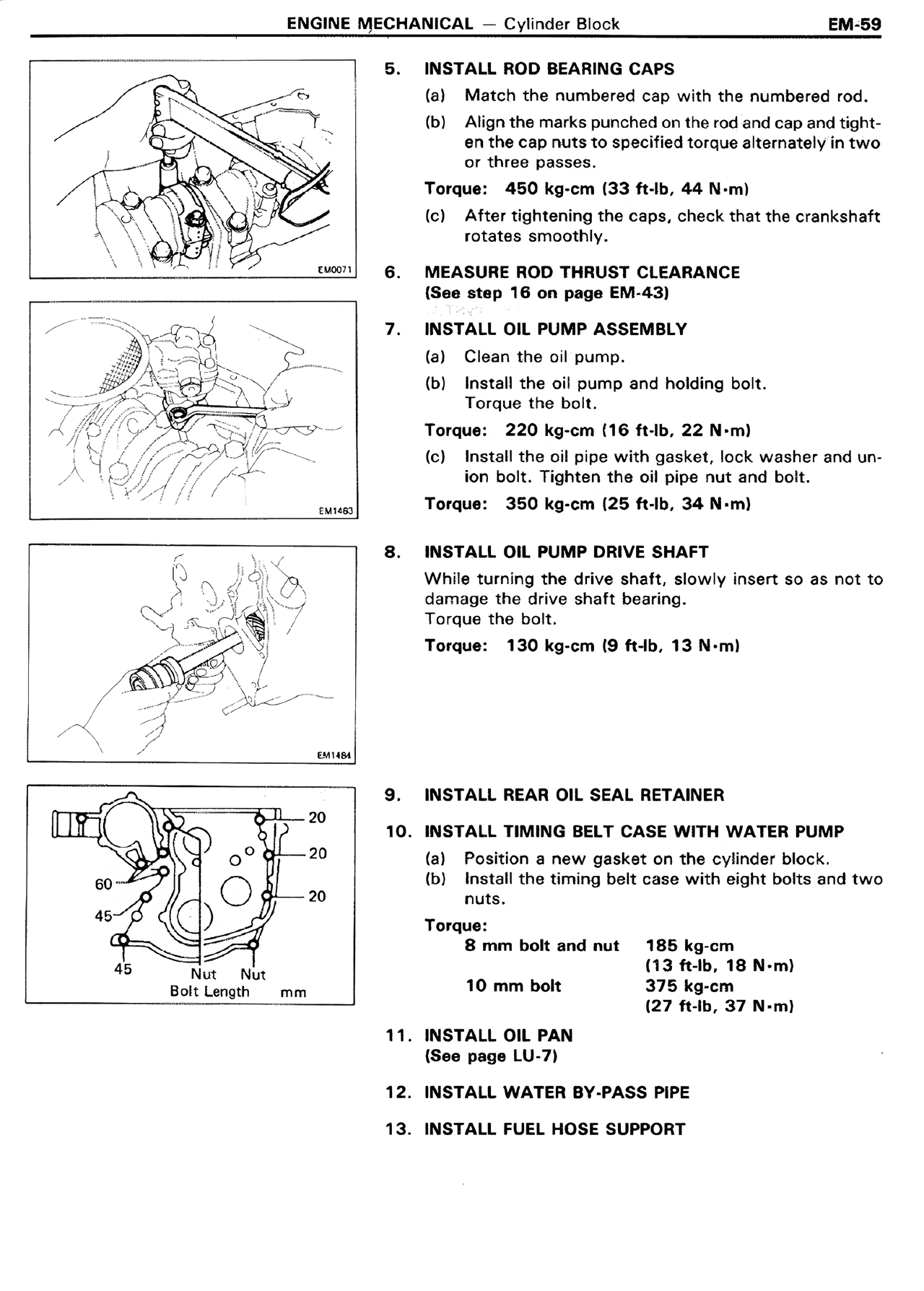

10. INSTALL TIMING BELT CASE WITH WATER PUMP

(a) Position a new gasket on the cylinder block.

(b) Install the timing belt case with eight bolts and two nuts.

Torque:

8 mm bolt and nut 186 kg-cm

(13 ft-lb, 18 N·m)

10 mm bolt 375 kg-cm

(27 ft-lb, 37 N·m)

11. INSTALL OIL PAN

(See page LU-7)

12. INSTALL WATER BY-PASS PIPE

13. INSTALL FUEL HOSE SUPPORT