TROUBLESHOOTING

Problem | Possible cause | Remedy | Page

Oil leakage | Cylinder head cylinder block or oil pump body damaged or cracked | Replace as necessary | LU-4

| Oil seal faulty | Replace oil seal |

| Gasket faulty | Replace gasket |

Low oil pressure | Oil leakage | Replace as necessary |

| Relief valve faulty | Replace relief valve | LU-4

| Oil pump faulty | Replace oil pump | LU-4

| Engine oil poor quality | Replace engine oil | LU-3

| Crankshaft bearing faulty | Replace bearing |

| Connecting rod bearing faulty | Replace bearing |

High oil pressure | Oil filter clogged | Replace oil filter | LU-3

| Relief valve faulty | Replace relief valve | LU-4

OIL PRESSURE CHECK

Recommended Viscosity (SAE)

10W-40 20W-40 20W-50

10W-30 10W-40 10W-50

5W-30

-40 -20 0 20 40 60 80 100

-40 -20 0 20 40 60 80 100

AMBIENT TEMPERATURE RANGE BEFORE NEXT OIL CHANGE

LU0211

[Diagram showing oil pressure gauge installation]

LU0601

1. CHECK OIL QUALITY

Check the oil for signs of deterioration, entry of water, discoloring or thinning.

If the quality is poor, change the oil.

Use API grade SF or SF/CC multigrade, fuel-efficient and recommended viscosity oil.

2. CHECK OIL LEVEL

The oil level should be between the L and F marks on the oil level gauge. If low, check for leakage and add oil up to the F mark.

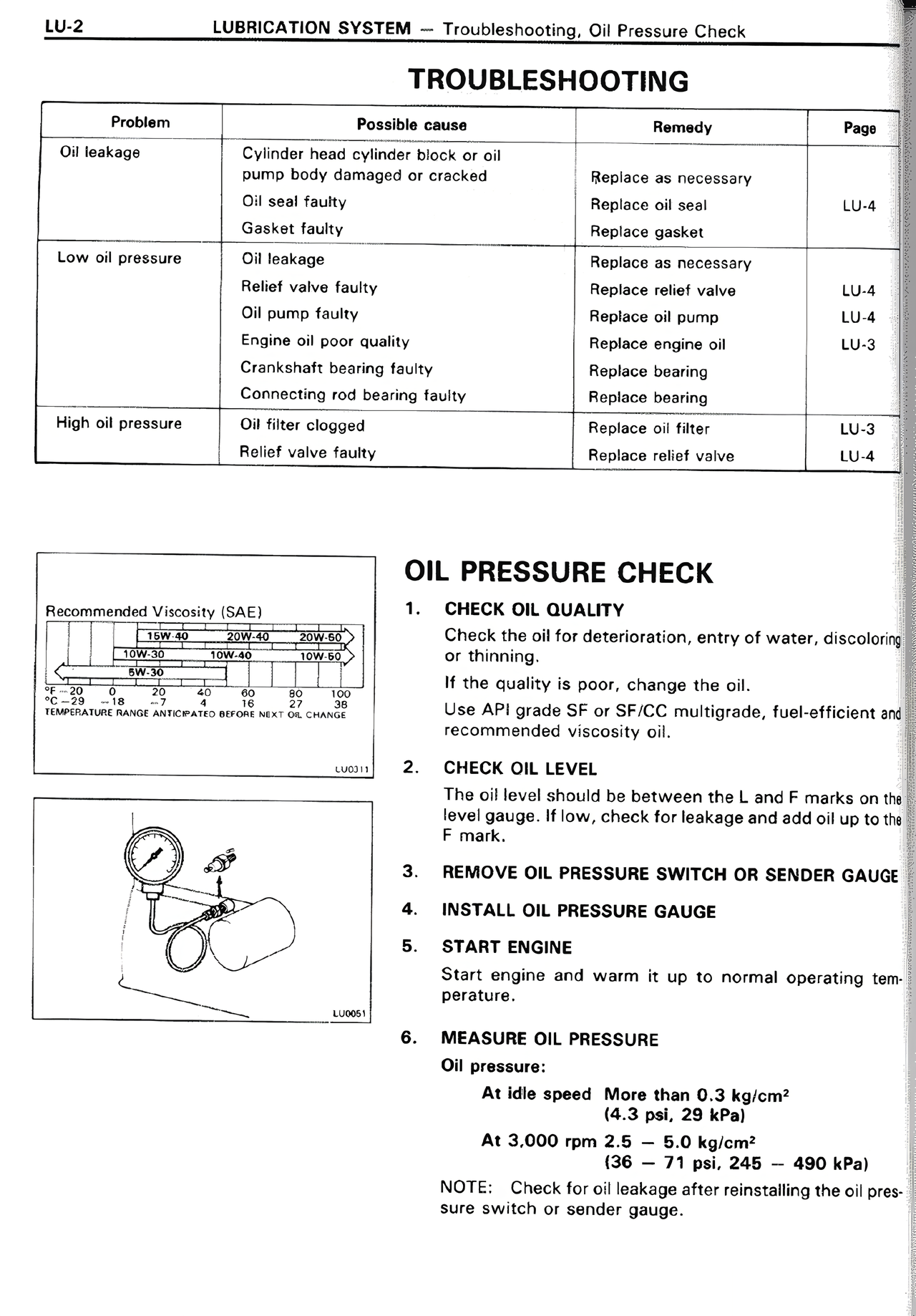

3. REMOVE OIL PRESSURE SWITCH OR SENDER GAUGE

4. INSTALL OIL PRESSURE GAUGE

5. START ENGINE

Start engine and warm it up to normal operating temperature.

6. MEASURE OIL PRESSURE

Oil pressure:

At idle speed More than 0.3 kg/cm²

(4.3 psi, 29 kPa)

At 3,000 rpm 2.5 — 5.0 kg/cm²

(36 — 71 psi, 245 — 490 kPa)

NOTE: Check for oil leakage after reinstalling the oil pressure switch or sender gauge.