LU-6

LUBRICATION SYSTEM — Oil Pump

INSPECTION OF OIL PUMP

1. INSPECT RELIEF VALVE

Check the relief valve for scoring or wear.

If damaged, replace the valve or pump assembly.

2. MEASURE BODY CLEARANCE

Using a feeler gauge, measure the clearance between the

driven gear and body.

Standard clearance: 0.03 - 0.08 mm

(0.0012 - 0.0024 in.)

Maximum clearance: 0.2 mm (0.008 in.)

If the clearance is greater than maximum, replace the gear

and/or body.

3. MEASURE GEAR BACKLASH

Using a feeler gauge, measure the backlash as shown.

Standard clearance: 0.5 - 0.8mm

(0.020 - 0.024 in.)

Maximum backlash: 0.9 mm (0.035 in.)

If the blaklash is greater than maximum, replace the shaft

subassembly and/or driven gear.

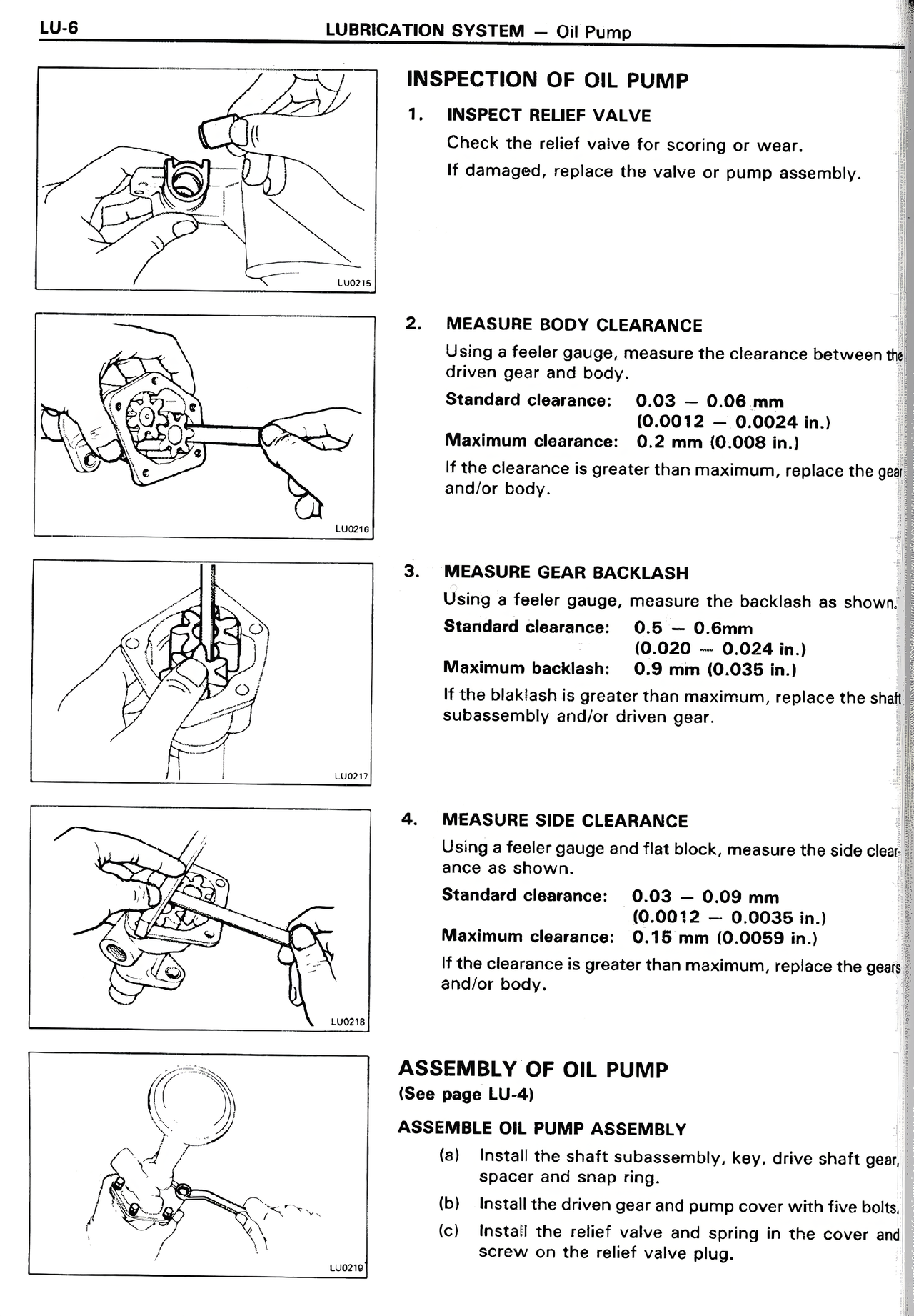

4. MEASURE SIDE CLEARANCE

Using a feeler gauge and flat block, measure the side clearance as shown.

Standard clearance: 0.03 - 0.09 mm

(0.0012 - 0.0035 in.)

Maximum clearance: 0.15 mm (0.0059 in.)

If the clearance is greater than maximum, replace the gears

and/or body.

ASSEMBLY OF OIL PUMP

(See page LU-4)

ASSEMBLE OIL PUMP ASSEMBLY

(a) Fit the shaft subassembly, key, drive shaft gear, drive

spacer and snap ring.

(b) Install the driven gear and pump cover with five bolts.

(c) Install the relief valve and spring in the cover and

screw on the relief valve plug.