OPERATION CHECK OF OIL PUMP

CHECK PUMP OPERATION

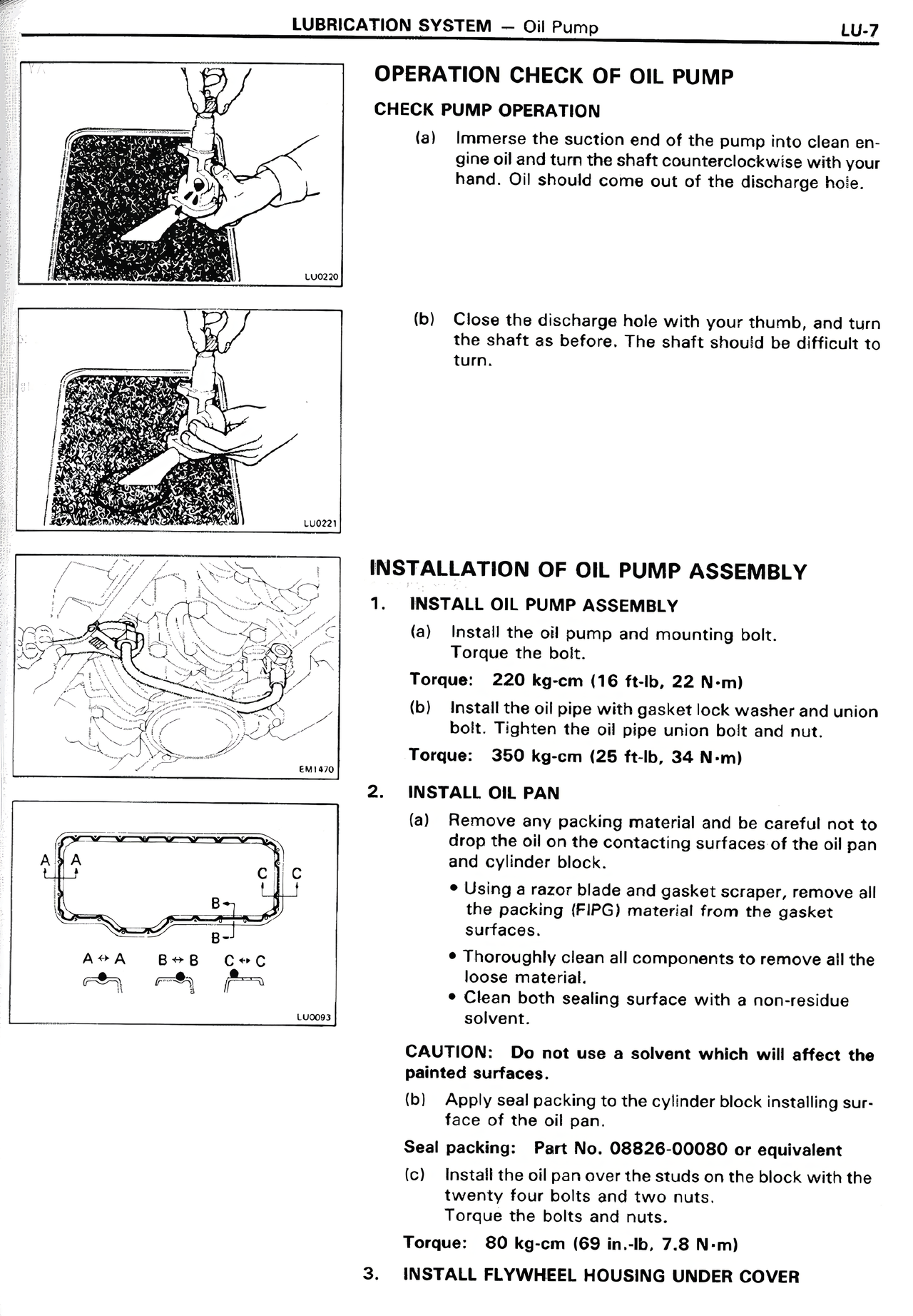

(a) Immerse the suction end of the pump into clean engine oil and turn the shaft counterclockwise with your hand. Oil should come out of the discharge hole.

(b) Close the discharge hole with your thumb, and turn the shaft as before. The shaft should be difficult to turn.

INSTALLATION OF OIL PUMP ASSEMBLY

1. INSTALL OIL PUMP ASSEMBLY

(a) Install the oil pump and mounting bolt. Torque the bolt.

Torque: 220 kg-cm (16 ft-lb, 22 N-m)

(b) Install the oil pipe with gasket lock washer and union bolt. Tighten the oil pipe union bolt and nut.

Torque: 350 kg-cm (25 ft-lb, 34 N-m)

2. INSTALL OIL PAN

(a) Remove any packing material and be careful not to drop the oil on the contacting surfaces of the oil pan and cylinder block.

• Using a razor blade and gasket scraper, remove all the packing (FIPG) material from the gasket surfaces.

• Thoroughly clean all components to remove all the loose material.

• Clean both sealing surface with a non-residue solvent.

CAUTION: Do not use a solvent which will affect the painted surfaces.

(b) Apply seal packing to the cylinder block installing surface of the oil pan.

Seal packing: Part No. 08826-00080 or equivalent

(c) Install the oil pan over the studs on the block with the twenty four bolts and two nuts. Torque the bolts and nuts.

Torque: 80 kg-cm (69 in.-lb, 7.8 N-m)

3. INSTALL FLYWHEEL HOUSING UNDER COVER