MAINTENANCE OPERATIONS

ENGINE

Cold Engine Operations

1. REPLACE TIMING BELT

(a) Remove the timing belt.

(See pages EM-11 to 13)

(b) Install the timing belt.

(See pages EM-15 to 17)

2. INSPECT V-RIBBED TYPE DRIVE BELT (ALTERNATOR) AND CONVENTIONAL TYPE DRIVE BELTS (PS PUMP AND A/C COMPRESSOR)

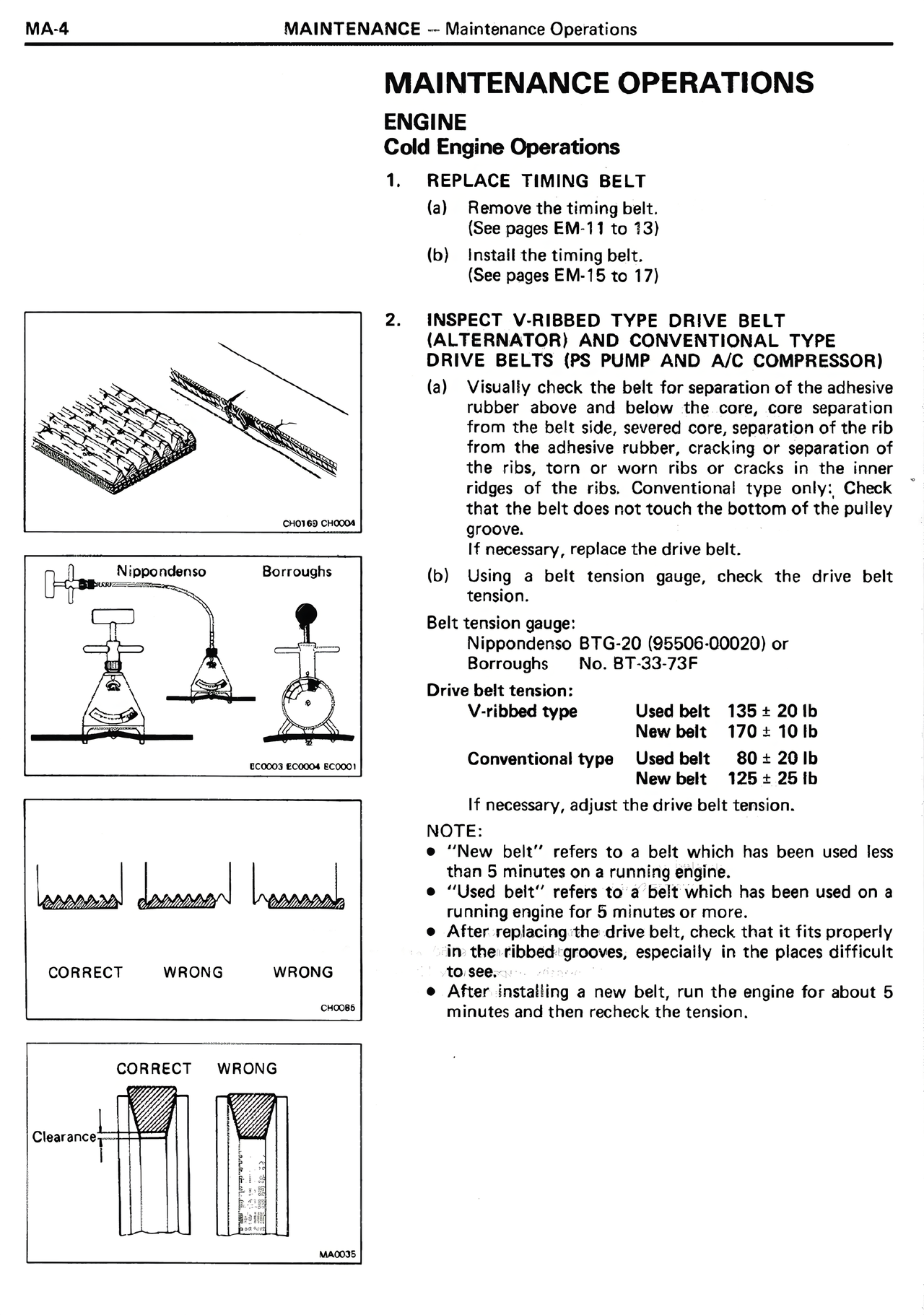

(a) Visually check the belt for separation of the adhesive rubber above and below the cord, cord separation from the belt side, severed cord, separation of the rib from the adhesive rubber, cracking or separation of the ribs, torn or worn ribs or cracks in the inner ridges of the ribs. Conventional type only: Check that the belt does not touch the bottom of the pulley groove.

If necessary, replace the drive belt.

(b) Using a belt tension gauge, check the drive belt tension.

Belt tension gauge:

Nippondenso BTG-20 (96506-00020) or

Borroughs No. BT-33-73F

Drive belt tension:

V-ribbed type Used belt 135 ± 20 lb

New belt 170 ± 10 lb

Conventional type Used belt 80 ± 20 lb

New belt 125 ± 25 lb

If necessary, adjust the drive belt tension.

NOTICE:

• "New belt" refers to a belt which has been used less than 5 minutes on a running engine.

• "Used belt" refers to a belt which has been used on a running engine for 5 minutes or more.

• After replacing the drive belt, check that it fits properly in the ribbed grooves, especially in the places difficult to see.

• After installing a new belt, run the engine for about 5 minutes and then recheck the tension.

CORRECT WRONG WRONG

CORRECT WRONG

Clearance