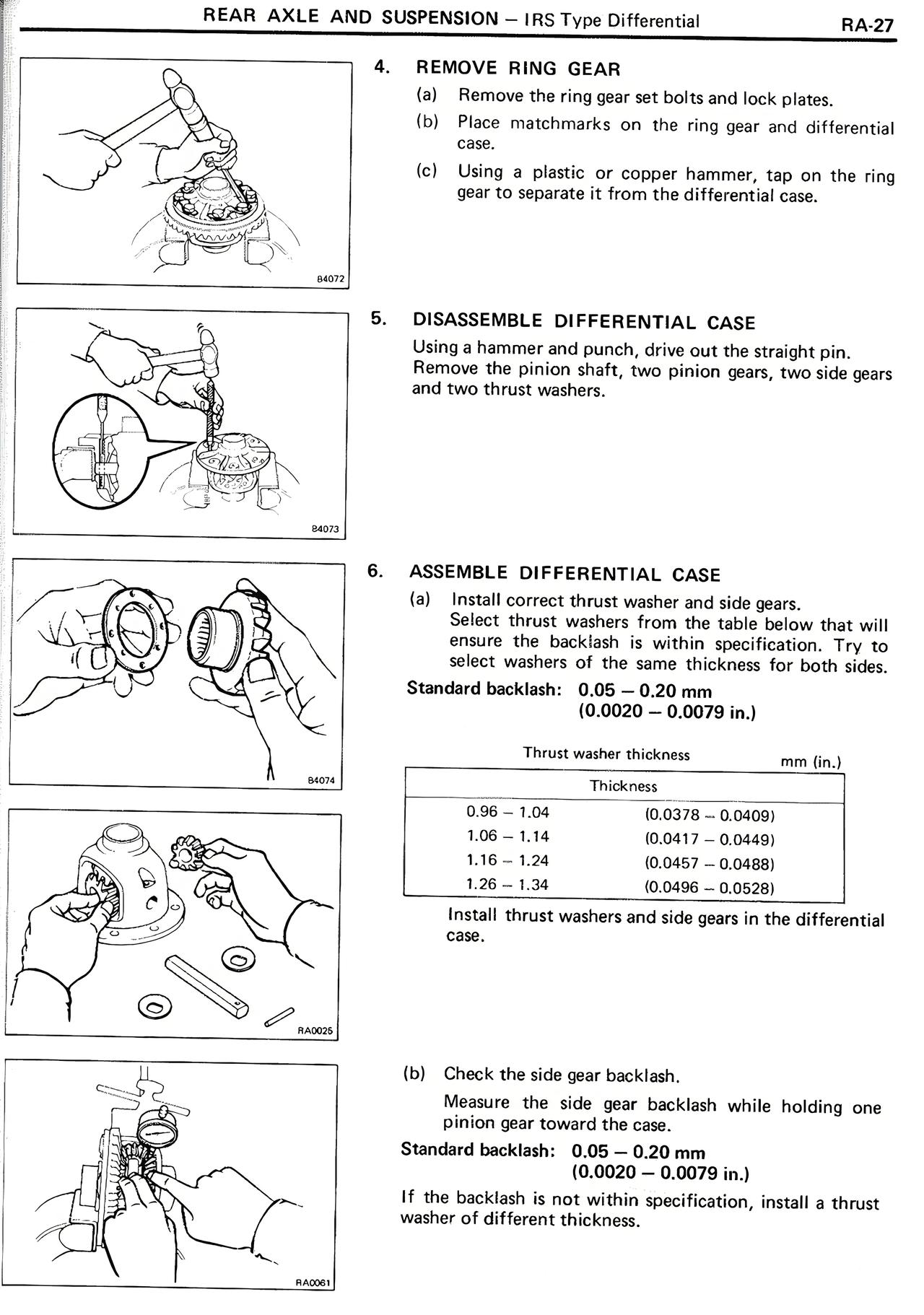

4. REMOVE RING GEAR

(a) Remove the ring gear set bolts and lock plates.

(b) Place matchmarks on the ring gear and differential case.

(c) Using a plastic or copper hammer, tap on the ring gear to separate it from the differential case.

5. DISASSEMBLE DIFFERENTIAL CASE

Using a hammer and punch, drive out the straight pin. Remove the pinion shaft, two pinion gears, two side gears and two thrust washers.

6. ASSEMBLE DIFFERENTIAL CASE

(a) Install correct pinion and side gears.

Select thrust washers from the table below that will ensure the backlash is within specification. Try to select washers of the same thickness for both sides.

Standard backlash: 0.05 — 0.20 mm

(0.0020 — 0.0079 in.)

Thrust washer thickness mm (in.)

Thickness

0.96 — 1.04 (0.0378 — 0.0409)

1.06 — 1.14 (0.0417 — 0.0449)

1.16 — 1.24 (0.0457 — 0.0488)

1.26 — 1.34 (0.0496 — 0.0528)

Install thrust washers and side gears in the differential case.

(b) Check the side gear backlash.

Measure the side gear backlash while holding one pinion gear toward the case.

Standard backlash: 0.05 — 0.20 mm

(0.0020 — 0.0079 in.)

If the backlash is not within specification, install a thrust washer of different thickness.