17. INSTALL SIDE GEAR SHAFT

(a) Before installing the shaft, replace the snap ring.

(b) Using a plastic hammer, drive in the side gear shaft until it contacts the pinion shaft.

NOTE: As the LSD cannot be checked visually, check that the shaft is fully inserted by confirming the sound it makes when it is tapped.

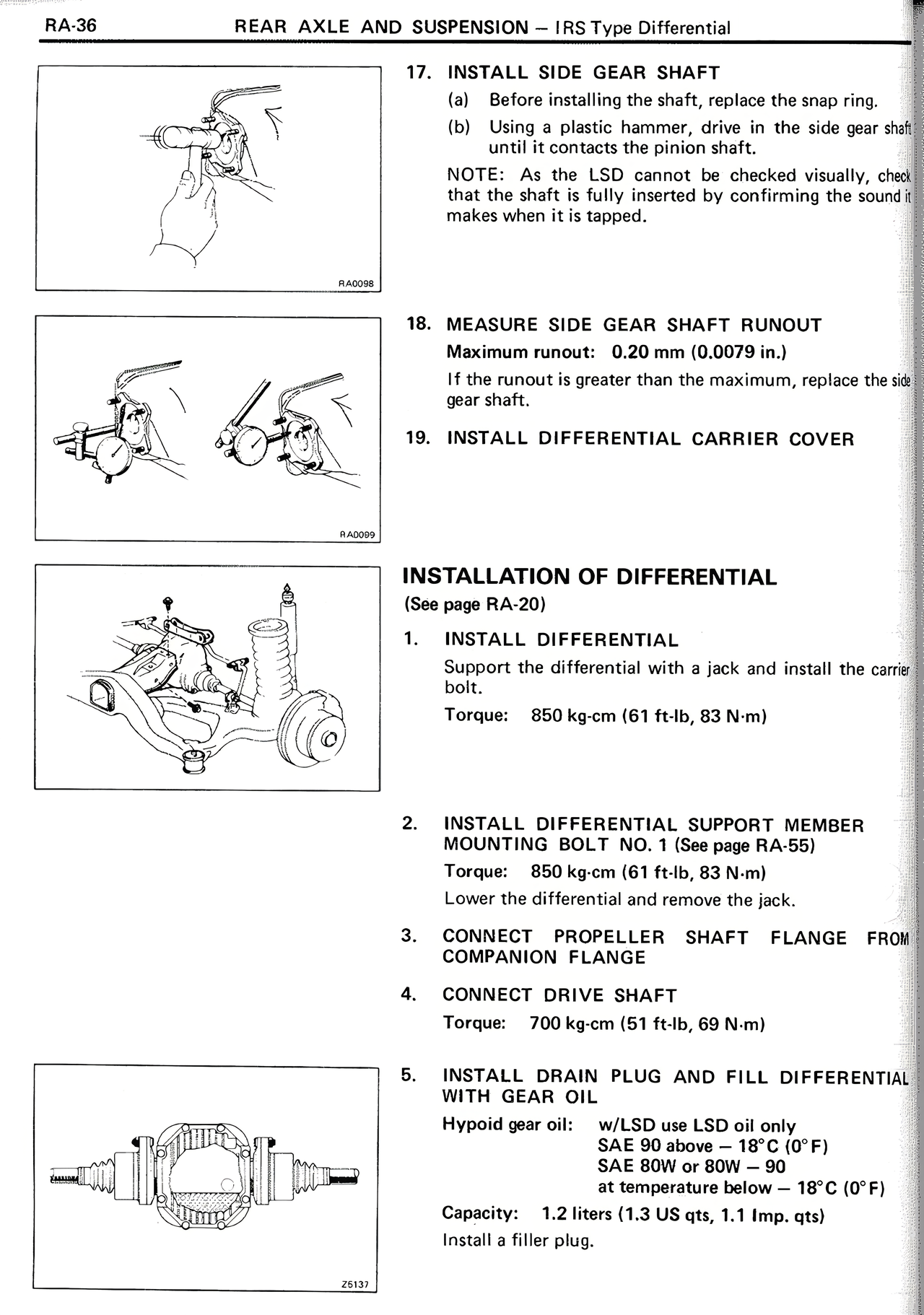

18. MEASURE SIDE GEAR SHAFT RUNOUT

Maximum runout: 0.20 mm (0.0079 in.)

If the runout is greater than the maximum, replace the side gear shaft.

19. INSTALL DIFFERENTIAL CARRIER COVER

INSTALLATION OF DIFFERENTIAL

(See page RA-20)

1. INSTALL DIFFERENTIAL

Support the differential with a jack and install the carrier bolt.

Torque: 850 kg-cm (61 ft-lb, 83 N-m)

2. INSTALL DIFFERENTIAL SUPPORT MEMBER MOUNTING BOLT NO. 1 (See page RA-55)

Torque: 850 kg-cm (61 ft-lb, 83 N-m)

Lower the differential and remove the jack.

3. CONNECT PROPELLER SHAFT FLANGE FROM COMPANION FLANGE

4. CONNECT DRIVE SHAFT

Torque: 700 kg-cm (51 ft-lb, 69 N-m)

5. INSTALL DRAIN PLUG AND FILL DIFFERENTIAL WITH GEAR OIL

Hypoid gear oil: w/LSD use LSD oil only

SAE 90 above — 18°C (0°F)

SAE 80W or 90W — 90

at temperature below — 18°C (0°F)

Capacity: 1.2 liters (1.3 US qts, 1.1 Imp. qts)

Install a filler plug.