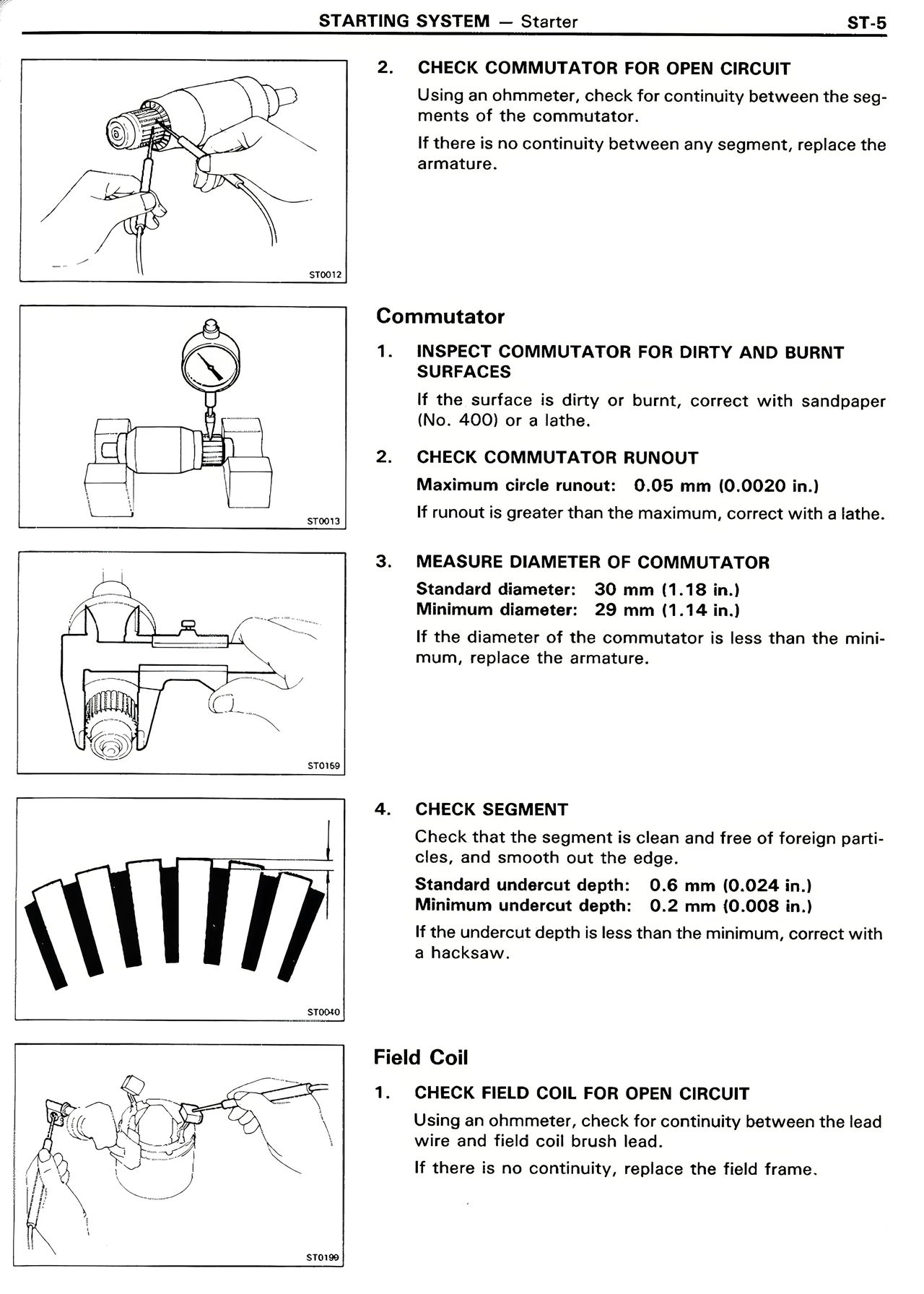

2. CHECK COMMUTATOR FOR OPEN CIRCUIT

Using an ohmmeter, check for continuity between the segments of the commutator.

If there is no continuity between any segment, replace the armature.

Commutator

1. INSPECT COMMUTATOR FOR DIRTY AND BURNT SURFACES

If dirty or burnt, correct with sandpaper (No. 400) or a lathe.

2. CHECK COMMUTATOR RUNOUT

Maximum circle runout: 0.05 mm (0.0020 in.)

If runout is greater than the maximum, correct with a lathe.

3. MEASURE DIAMETER OF COMMUTATOR

Standard diameter: 30 mm (1.18 in.)

Minimum diameter: 29 mm (1.14 in.)

If the diameter of the commutator is less than the minimum, replace the armature.

4. CHECK SEGMENT

Check that the segment is clean and free of foreign particles, and smooth out the edge.

Standard undercut depth: 0.6 mm (0.024 in.)

Minimum undercut depth: 0.2 mm (0.008 in.)

If the undercut depth is less than the minimum, correct with a hacksaw.

Field Coil

1. CHECK FIELD COIL FOR OPEN CIRCUIT

Using an ohmmeter, check for continuity between the lead wire and field coil brush lead.

If there is no continuity, replace the field frame.