TROUBLESHOOTING

How To Proceed With Troubleshooting

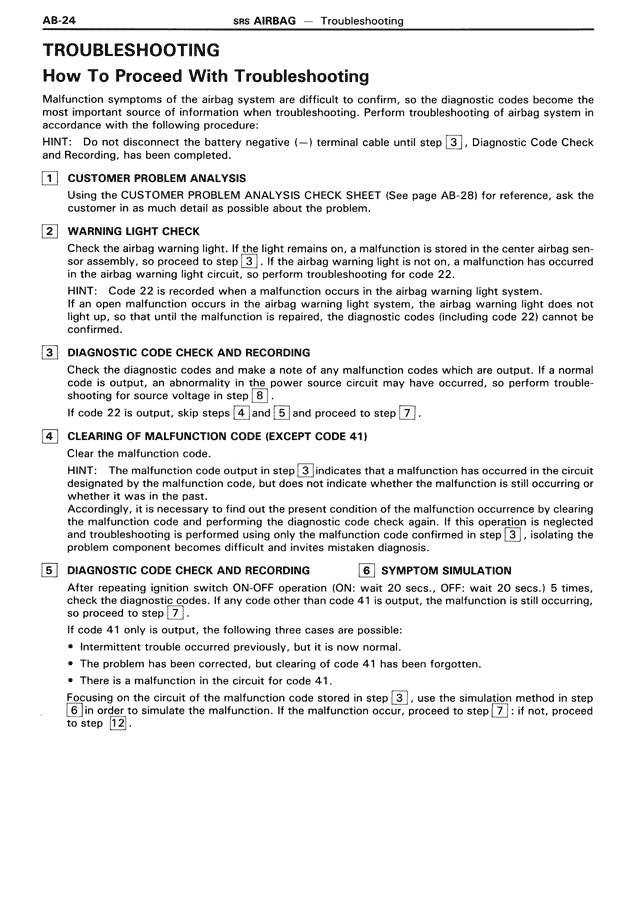

Malfunction symptoms of the airbag system are difficult to confirm, so the diagnostic codes become the most important source of information when troubleshooting. Perform troubleshooting of airbag system in accordance with the following procedure:

HINT: Do not disconnect the battery negative (—) terminal cable until step 3, Diagnostic Code Check and Recording, has been completed.

1 CUSTOMER PROBLEM ANALYSIS

Using the CUSTOMER PROBLEM ANALYSIS CHECK SHEET (See page AB-28) for reference, ask the customer in as much detail as possible about the problem.

2 WARNING LIGHT CHECK

Check the airbag warning light. If the light remains on, it indicates a malfunction in the airbag sensor assembly, so proceed to step 3. If the airbag warning light is not on, a malfunction has occurred in the airbag warning light circuit, so perform troubleshooting for code 22.

HINT: Code 22 is recorded when a malfunction occurs in the airbag warning light system. If an open malfunction occurs in the airbag warning light system, the airbag warning light does not light up, so that until the malfunction is repaired, the diagnostic codes (including code 22) cannot be confirmed.

3 DIAGNOSTIC CODE CHECK AND RECORDING

Check the diagnostic codes and make a note of any malfunction codes which are output. If a normal code is output, an abnormality in the power source circuit may have occurred, so perform troubleshooting for source voltage in step 8.

If code 22 is output, skip steps 4 and 5 and proceed to step 7.

4 CLEARING OF MALFUNCTION CODE (EXCEPT CODE 41)

Clear the malfunction code.

HINT: The malfunction code output in step 3 indicates that a malfunction has occurred in the circuit designated by the malfunction code, but does not indicate whether the malfunction is still occurring or whether it was in the past.

Accordingly, it is necessary to find out the present condition of the malfunction occurrence by clearing the malfunction code and performing the diagnostic code check again. If this operation is registered and troubleshooting is performed using only the malfunction code confirmed in step 3, isolating the problem component becomes difficult and invites mistaken diagnosis.

5 DIAGNOSTIC CODE CHECK AND RECORDING

After repeating ignition switch ON-OFF operation (ON: wait 20 secs., OFF: wait 20 secs.) 5 times, check the diagnostic codes. If any code other than code 41 is output, the malfunction is still occurring, so proceed to step 7.

If code 41 only is output, the following three cases are possible:

• Intermittent trouble occurred previously, but it is now normal.

• The problem has been corrected, but clearing of code 41 has been forgotten.

• There is a malfunction in the circuit for code 41.

Focusing on the circuit of the malfunction code stored in step 3, use the simulation method in step 6 in order to simulate the malfunction. If the malfunction occur, proceed to step 7; if not, proceed to step 12.

6 SYMPTOM SIMULATION