Checking of Refrigeration System with Manifold Gauge

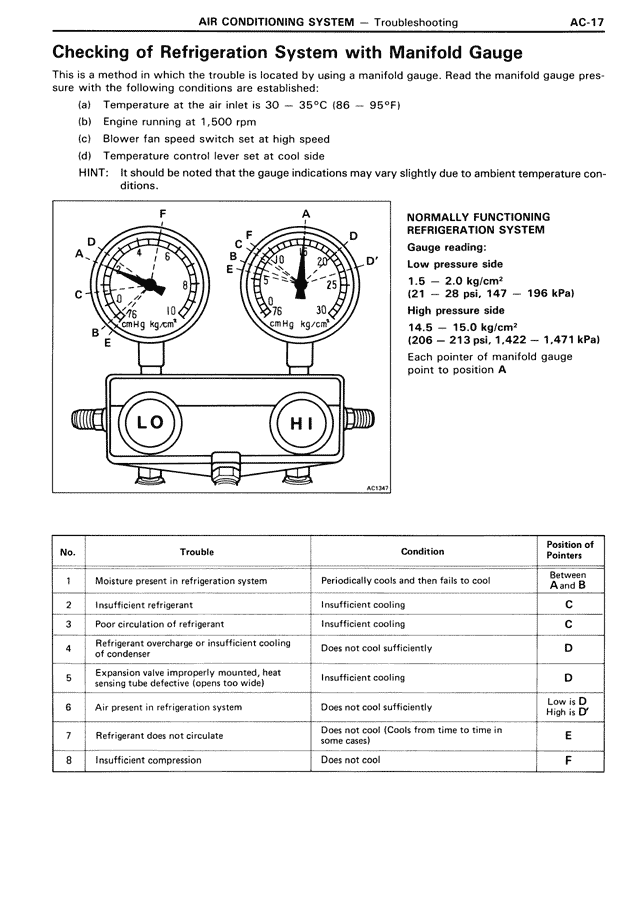

This is a method in which the trouble is located by using a manifold gauge. Read the manifold gauge pressure with the following conditions are established:

(a) Temperature at the air inlet is 30 — 35°C (86 — 95°F)

(b) Engine running at 1,500 rpm

(c) Blower fan speed switch set at high speed

(d) Temperature control lever set at cool side

HINT: It should be noted that the gauge indications may vary slightly due to ambient temperature conditions.

NORMALLY FUNCTIONING

REFRIGERATION SYSTEM

Gauge reading:

Low pressure side

1.5 — 2.0 kg/cm²

(21 — 28 psi, 147 — 196 kPa)

High pressure side

14.5 — 15.0 kg/cm²

(206 — 213 psi, 1,422 — 1,471 kPa)

Each pointer of manifold gauge

point to position A

No. | Trouble | Condition | Position of Pointers

1 | Moisture present in refrigeration system | Periodically cools and then fails to cool | Between A and B

2 | Insufficient refrigerant | Insufficient cooling | C

3 | Poor circulation of refrigerant | Insufficient cooling | C

4 | Refrigerant overcharge or insufficient cooling of condenser | Does not cool sufficiently | D

5 | Expansion valve improperly mounted, heat sensing tube defective (opened too wide) | Insufficient cooling | D

6 | Air present in refrigeration system | Does not cool sufficiently | Low in D High in D'

7 | Refrigerant does not circulate | Does not cool (Cools from time to time in some case) | E

8 | Insufficient compression | Does not cool | F