AC-18

AIR CONDITIONING SYSTEM — Troubleshooting

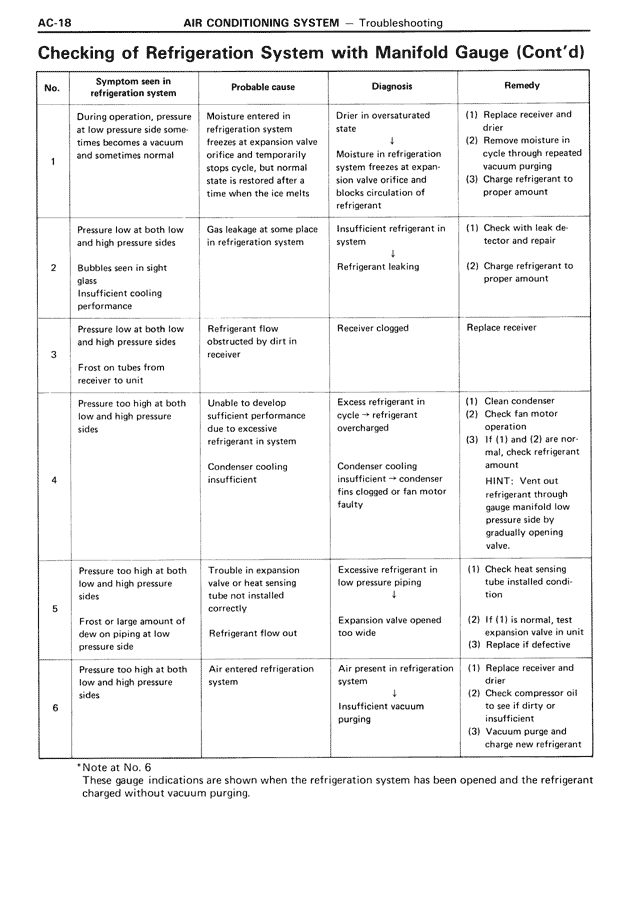

Checking of Refrigeration System with Manifold Gauge (Cont'd)

No. | Symptom seen in refrigeration system | Probable cause | Diagnosis | Remedy

1 | During operation, pressure at low pressure side sometimes becomes a vacuum and sometimes normal | Moisture entered in refrigeration system freezes at expansion valve orifice and temporarily stops cycle, but normal state is restored after a time when the ice melts | Drier in oversaturated state

↓

Moisture in refrigeration system freezes at expansion valve orifice and blocks circulation of refrigerant | (1) Replace receiver and drier

(2) Remove moisture in cycle through repeated vacuum purging

(3) Charge refrigerant to proper amount

2 | Pressure low at both low and high pressure sides

Bubbles seen in sight glass

Insufficient cooling performance | Gas leakage at some place in refrigeration system | Insufficient refrigerant in system

↓

Refrigerant leaking | (1) Check with leak detector and repair

(2) Charge refrigerant to proper amount

3 | Pressure low at both low and high pressure sides

Frost on tubes from receiver to unit | Refrigerant flow obstructed by dirt in receiver | Receiver clogged | Replace receiver

4 | Pressure too high at both low and high pressure sides | Unable to develop sufficient performance due to excessive refrigerant in system

Condenser cooling insufficient | Excess refrigerant in cycle → refrigerant overcharged

↓

Condenser cooling insufficient → condenser fins clogged or fan motor faulty | (1) Clean condenser

(2) Check fan motor operation

(3) If (1) and (2) are normal, check refrigerant amount

HINT: Vent out refrigerant through gauge manifold low pressure side by gradually opening valve.

5 | Pressure too high at both low and high pressure sides

Frost or large amount of dew on piping at low pressure side | Trouble in expansion valve or heat sensing tube not installed correctly

Refrigerant flow cut off | Excessive refrigerant in low pressure piping

↓

Expansion valve opened too wide | (1) Check heat sensing tube installation condition

(2) If (1) is normal, test expansion valve in unit

(3) Replace if defective

6 | Pressure too high at both low and high pressure sides | Air entered refrigeration system | Air present in refrigeration system

↓

Insufficient vacuum purging | (1) Replace receiver and drier

(2) Check compressor oil to see if dirty or insufficient

(3) Vacuum purge and charge new refrigerant

*Note at No. 6

These gauge indications are shown when the refrigeration system has been opened and the refrigerant charged without vacuum purging.