GENERAL DESCRIPTION

REFRIGERATION CYCLE

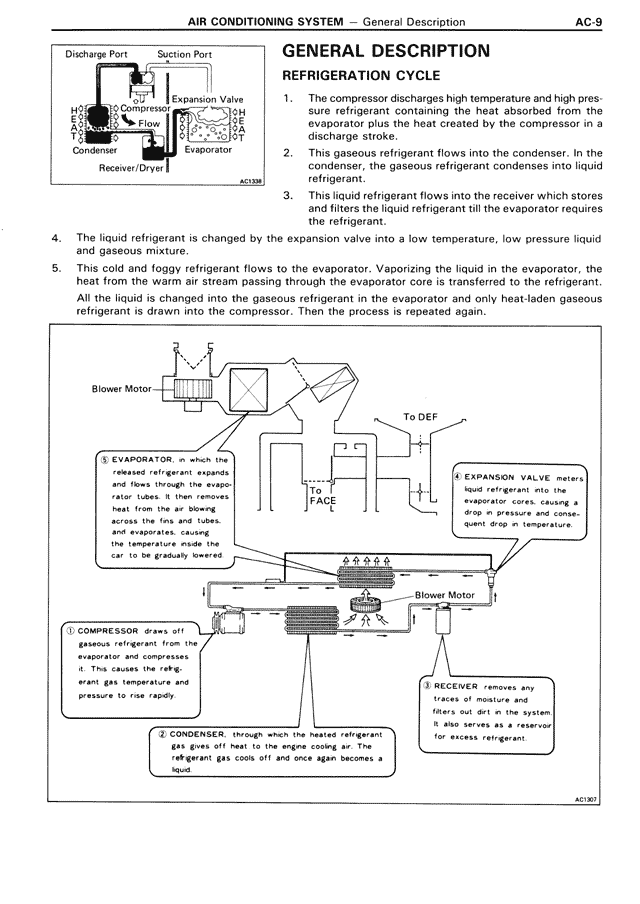

1. The compressor discharges high temperature and high pressure gaseous refrigerant containing the heat absorbed from the evaporator plus the heat created by the compressor at its discharge stroke.

2. This gaseous refrigerant flows into the condenser. In the condenser, the gaseous refrigerant condenses into liquid refrigerant.

3. This liquid refrigerant flows into the receiver which stores and filters the liquid refrigerant till the evaporator requires the refrigerant.

4. The liquid refrigerant is changed by the expansion valve into a low temperature, low pressure liquid and gaseous mixture.

5. This cold and foggy refrigerant flows to the evaporator. Vaporizing the liquid in the evaporator, the heat from the warm air stream passing through the evaporator core is transferred to the refrigerant. All the liquid is changed into the gaseous refrigerant in the evaporator and only heat-laden gaseous refrigerant is drawn into the compressor. Then the process is repeated again.

3. EVAPORATOR, in which the released refrigerant gas expands and flows through the evaporator tubes. It then removes heat from the air blowing across the fins and tubes and thus lowers the temperature inside the car to be approximately several degrees cooler than outside.

6. EXPANSION VALVE meters liquid refrigerant into the evaporator. This creates a drop in pressure and consequent drop in temperature.

1. COMPRESSOR draws off gaseous refrigerant from the evaporator and compresses it to a rapidly rising great gas temperature and pressure to rise rapidly.

4. RECEIVER removes any excess moisture and filters out dirt in the system. It also serves as a reservoir for excess refrigerant.

2. CONDENSER, through which the heated refrigerant gas gives off heat to the engine cooling air. The refrigerant gas cools off and once again becomes a liquid.