27. INSTALL OIL PUMP INTO CASE

(a) Coat the race with petroleum jelly and install it onto the oil pump.

HINT: Race diameter

mm (in.)

Inside Outside

Race 28.1 (1.106) 47.3 (1.862)

(b) Coat the new O-ring with ATF and install it around the pump body.

(c) Place the oil pump through the input shaft, and align the bolt holes of the pump body with the transmission case.

(d) Hold the input shaft, and lightly press the oil pump body to slide the oil seal rings into the O/D direct clutch drum.

NOTICE: Do not push on the oil pump strongly, or the oil seal ring will stick to the direct clutch drum.

(e) Install the seven bolts.

Torque: 220 kg-cm (16 ft-lb, 22 N-m)

28. CHECK INPUT SHAFT ROTATION

Make sure the input shaft rotates smoothly.

29. INSTALL THROTTLE CABLE

(a) Coat a new O-ring with ATF and install it to the cable.

(b) Install the cable to the case.

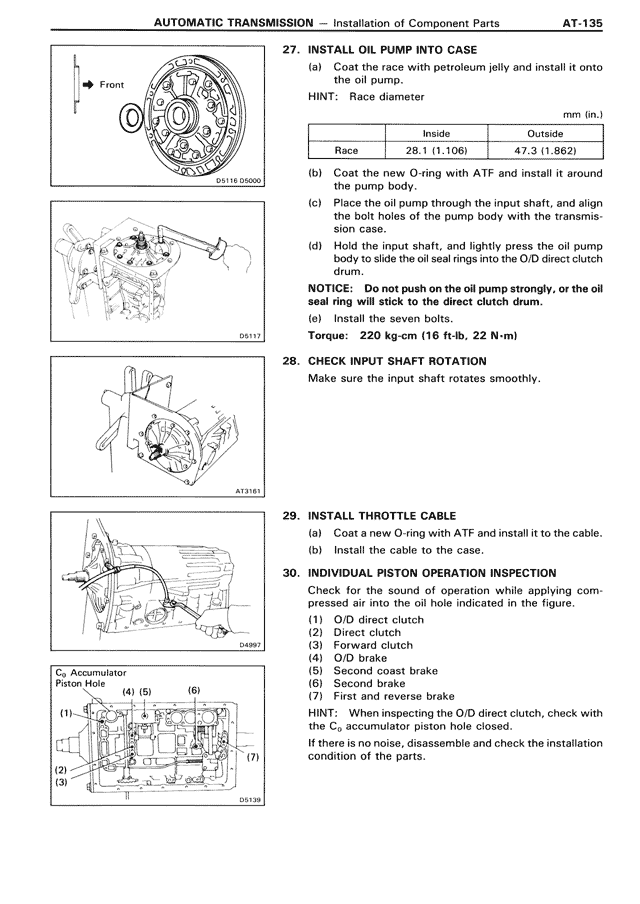

30. INDIVIDUAL PISTON OPERATION INSPECTION

Check for the sound of operation while applying compressed air into the oil hole indicated in the figure.

(1) O/D direct clutch

(2) Direct clutch

(3) Forward clutch

(4) O/D brake

(5) Second coast brake

(6) Second brake

(7) First and reverse brake

HINT: When inspecting the O/D direct clutch, check with the C0 accumulator piston hole closed.

If there is no noise, disassemble and check the installation condition of the parts.

C0 Accumulator

Piston Hole

(4) (5) (6)

(1)

(7)

(2)

(3)