AUTOMATIC TRANSMISSION — Troubleshooting (Mechanical System Tests) AT-33

(d) If the stall speed in R range is higher than specified without the rear wheels rotating:

• Line pressure too low

• Direct clutch slipping

• First and reverse brake slipping

• O/D one-way clutch not operating properly

(e) If the stall speed in both R and D ranges are higher than specified without the rear wheels rotating:

• Line pressure too low

• Improper fluid level

• O/D one-way clutch not operating properly

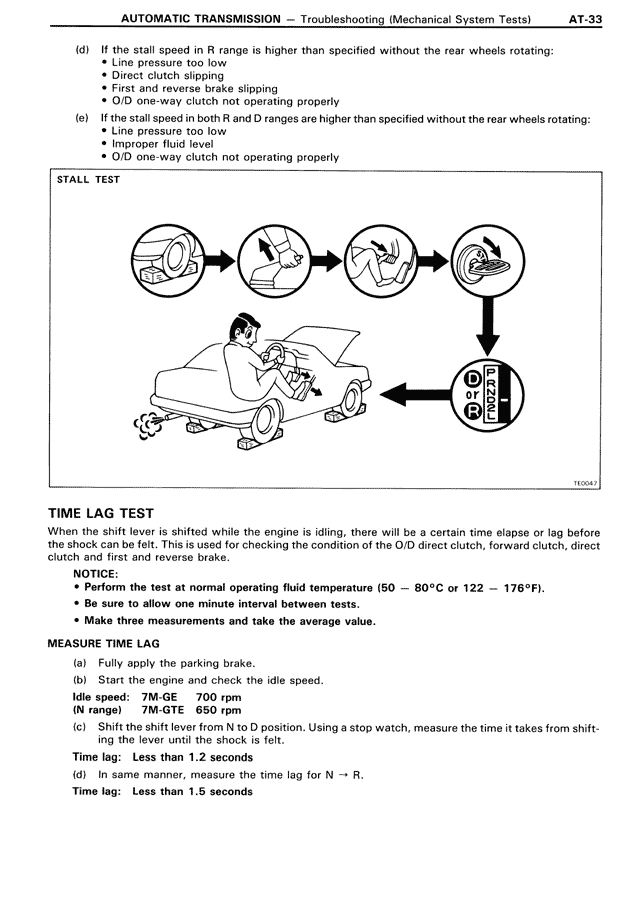

STALL TEST

[THIS IS FIGURE: A series of 5 circular diagrams showing stall test procedure, including gauges and a car on blocks, connected by arrows, labeled TEC047]

TIME LAG TEST

When the shift lever is shifted while the engine is idling, there will be a certain time elapse or lag before the shock can be felt. This is used for checking the condition of the O/D direct clutch, forward clutch, direct clutch and first and reverse brake.

NOTICE:

• Perform the test at normal operating fluid temperature (50 — 80°C or 122 — 176°F).

• Be sure to allow one minute interval between tests.

• Make three measurements and take the average value.

MEASURE TIME LAG

(a) Fully apply the parking brake.

(b) Start the engine and check the idle speed.

Idle speed: 7M-GE 700 rpm

(N range) 7M-GTE 650 rpm

(c) Shift the shift lever from N to D position. Using a stop watch, measure the time it takes from shifting the lever until the shock is felt.

Time lag: Less than 1.2 seconds

(d) In same manner, measure the time lag for N → R.

Time lag: Less than 1.5 seconds