Diagnosis System

DESCRIPTION

If a malfunction occurs, the system will identify the problem and the computer will store the codes for the trouble items.

At the same time, it informs the driver of a malfunction via the "ANTILOCK" warning light in the instrument panel.

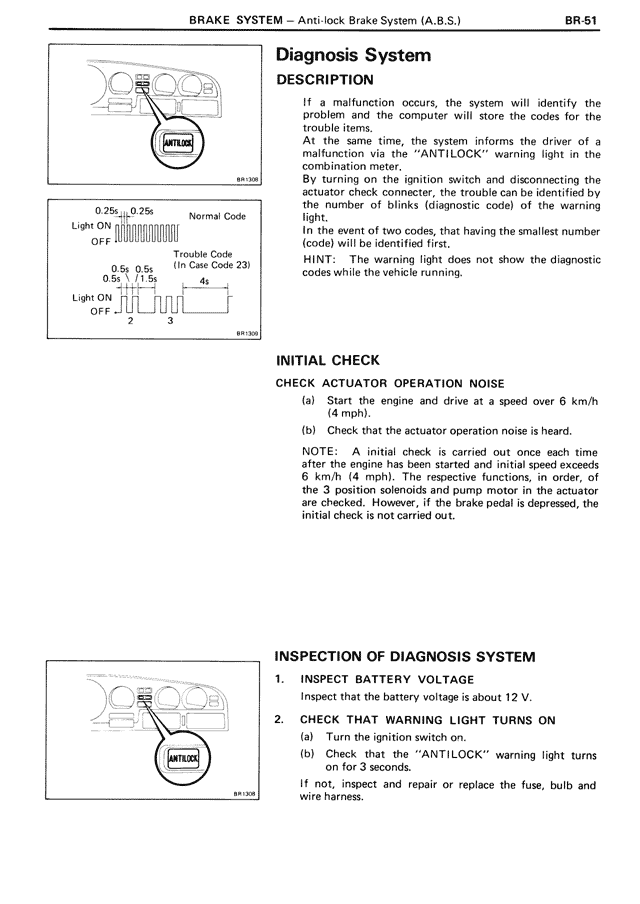

By turning on the ignition switch and disconnecting the actuator check connector, the trouble can be identified by the number of blinks (diagnostic code) of the warning light.

In the event of two codes, that having the smallest number (code) will be identified first.

HINT: The warning light does not show the diagnostic codes while the vehicle running.

INITIAL CHECK

CHECK ACTUATOR OPERATION NOISE

(a) Start the engine and drive at a speed over 6 km/h (4 mph).

(b) Check that the actuator operation noise is heard.

NOTE: A initial check is carried out once each time after the engine has been started and initial speed exceeds 6 km/h (4 mph). The respective functions, in order, of the 3 position solenoids and pump motor in the actuator are checked. However, if the brake pedal is depressed, the initial check is not carried out.

INSPECTION OF DIAGNOSIS SYSTEM

1. INSPECT BATTERY VOLTAGE

Inspect that the battery voltage is about 12 V.

2. CHECK THAT WARNING LIGHT TURNS ON

(a) Turn the ignition switch on.

(b) Check that the "ANTILOCK" warning light turns on for 3 seconds.

If not, inspect and repair or replace the fuse, bulb and wire harness.