3. INSPECT DRIVE BELT

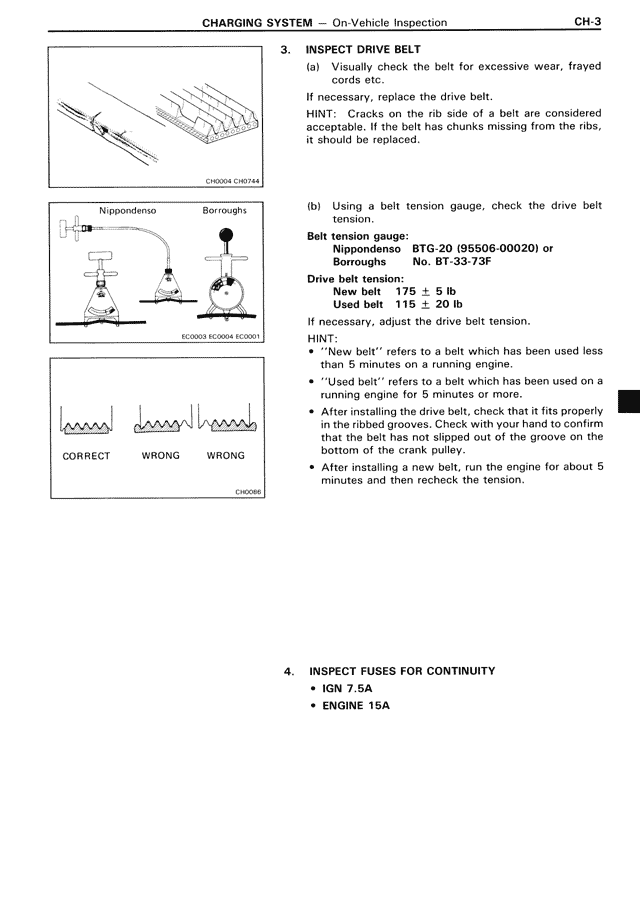

(a) Visually check the belt for excessive wear, frayed cords etc.

If necessary, replace the drive belt.

HINT: Cracks on the rib side of a belt are considered acceptable. If the belt has chunks missing from the ribs, it should be replaced.

(b) Using a belt tension gauge, check the drive belt tension.

Belt tension gauge:

Nippondenso BTG-20 (95506-00020) or

Borroughs No. BT-33-73F

Drive belt tension:

New belt 175 ± 5 lb

Used belt 115 ± 20 lb

If necessary, adjust the drive belt tension.

HINT:

• "New belt" refers to a belt which has been used less than 5 minutes on a running engine.

• "Used belt" refers to a belt which has been used on a running engine for 5 minutes or more.

• After installing the drive belt, check that it fits properly in the ribbed grooves. Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the crank pulley.

• After installing a new belt, run the engine for about 5 minutes and then recheck the tension.

4. INSPECT FUSES FOR CONTINUITY

• IGN 7.5A

• ENGINE 15A