INSPECTION OF EGR SYSTEM

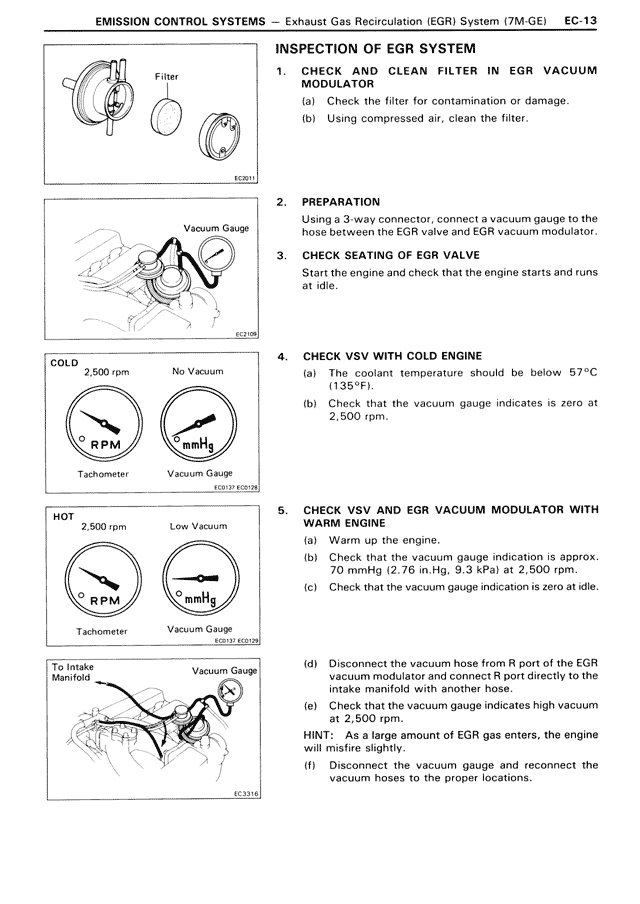

1. CHECK AND CLEAN FILTER IN EGR VACUUM MODULATOR

(a) Check the filter for contamination or damage.

(b) Using compressed air, clean the filter.

2. PREPARATION

Using a 3-way connector, connect a vacuum gauge to the hose between the EGR valve and EGR vacuum modulator.

3. CHECK SEATING OF EGR VALVE

Start the engine and check that the engine starts and runs at idle.

4. CHECK VSV WITH COLD ENGINE

(a) The coolant temperature should be below 57°C (135°F).

(b) Check that the vacuum gauge indicates is zero at 2,500 rpm.

5. CHECK VSV AND EGR VACUUM MODULATOR WITH WARM ENGINE

(a) Warm up the engine.

(b) Check that the vacuum gauge indication is approx. 70 mmHg (2.76 in.Hg, 9.3 kPa) at 2,500 rpm.

(c) Check that the vacuum gauge indication is zero at idle.

(d) Disconnect the vacuum hose from R port of the EGR vacuum modulator and connect R port directly to the intake manifold with another hose.

(e) Check that the vacuum gauge indicates high vacuum at 2,500 rpm.

HINT: As a large amount of EGR gas enters, the engine will misfire slightly.

(f) Disconnect the vacuum gauge and reconnect the vacuum hoses to the proper locations.