ENGINE MECHANICAL — Cylinder Head EM-47

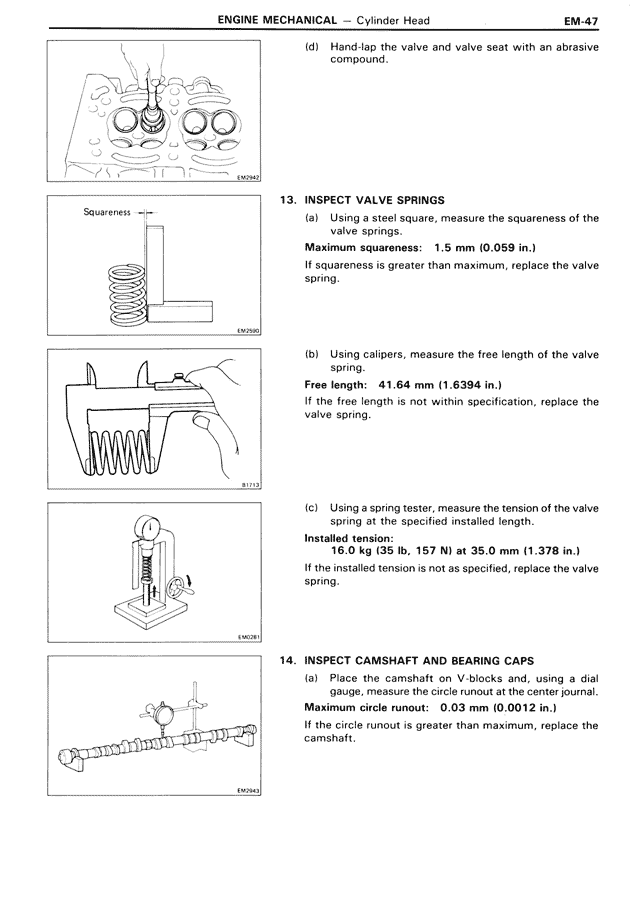

(d) Hand-lap the valve and valve seat with an abrasive

compound.

13. INSPECT VALVE SPRINGS

(a) Using a steel square, measure the squareness of the

valve springs.

Maximum squareness: 1.5 mm (0.059 in.)

If squareness is greater than maximum, replace the valve

spring.

(b) Using calipers, measure the free length of the valve

spring.

Free length: 41.64 mm (1.6394 in.)

If the free length is not within specification, replace the

valve spring.

(c) Using a spring tester, measure the tension of the valve

spring at the specified installed length.

Installed tension:

16.0 kg (35. lb. 157 N) at 35.0 mm (1.378 in.)

If the installed tension is not as specified, replace the valve

spring.

14. INSPECT CAMSHAFT AND BEARING CAPS

(a) Place the camshaft on V blocks and, using a dial

gauge, measure the circle runout at the center journal.

Maximum circle runout: 0.03 mm (0.0012 in.)

If circle runout is greater than maximum, replace the

camshaft.