EM-48

ENGINE MECHANICAL — Cylinder Head

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

Intake 7M-GE 38.16 mm (1.5024 in.)

7M-GTE 38.35 mm (1.5098 in.)

Exhaust 38.35 mm (1.5098 in.)

Minimum cam lobe height:

Intake 7M-GE 37.85 mm (1.4902 in.)

7M-GTE 38.00 mm (1.4961 in.)

Exhaust 38.00 mm (1.4961 in.)

If the cam lobe height is less than minimum, replace the camshaft.

(c) Using a micrometer, measure the journal diameter.

Standard diameter:

No.1 Journal

26.965 mm (1.0610 — 1.0616 in.)

No.2 — No.7 journals

26.888 — 26.975 mm (1.0586 — 1.0620 in.)

If the journal diameter is less than specified, replace the camshaft.

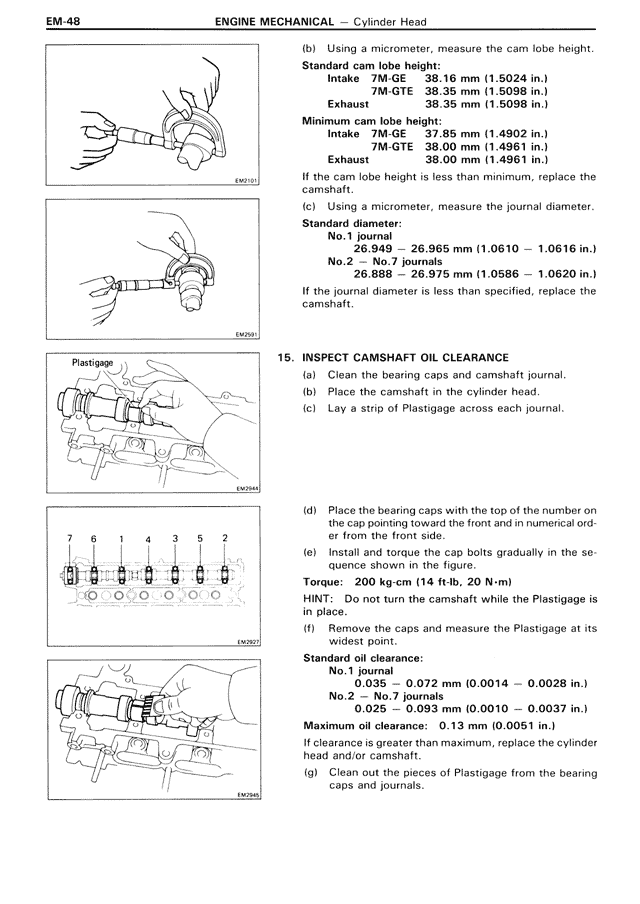

15. INSPECT CAMSHAFT OIL CLEARANCE

(a) Clean the bearing caps and camshaft journal.

(b) Place the camshaft in the cylinder head.

(c) Lay a strip of Plastigage on each journal.

(d) Place the bearing caps with the top of the number on the cap pointing toward the front and in numerical order from the front side.

(e) Install and torque the cap bolts gradually in the sequence shown in the figure.

Torque: 200 kg-cm (14 ft-lb, 20 N-m)

HINT: Do not turn the camshaft while the Plastigage is in place.

(f) Remove the caps and measure the Plastigage at its widest point.

Standard oil clearance:

No.1 Journal

0.035 — 0.072 mm (0.0014 — 0.0028 in.)

No.2 — No.7 journals

0.025 — 0.093 mm (0.0010 — 0.0037 in.)

Maximum oil clearance: 0.13 mm (0.0051 in.)

If clearance is greater than maximum, replace the cylinder head and/or camshaft.

(g) Clean out the pieces of Plastigage from the bearing caps and journals.