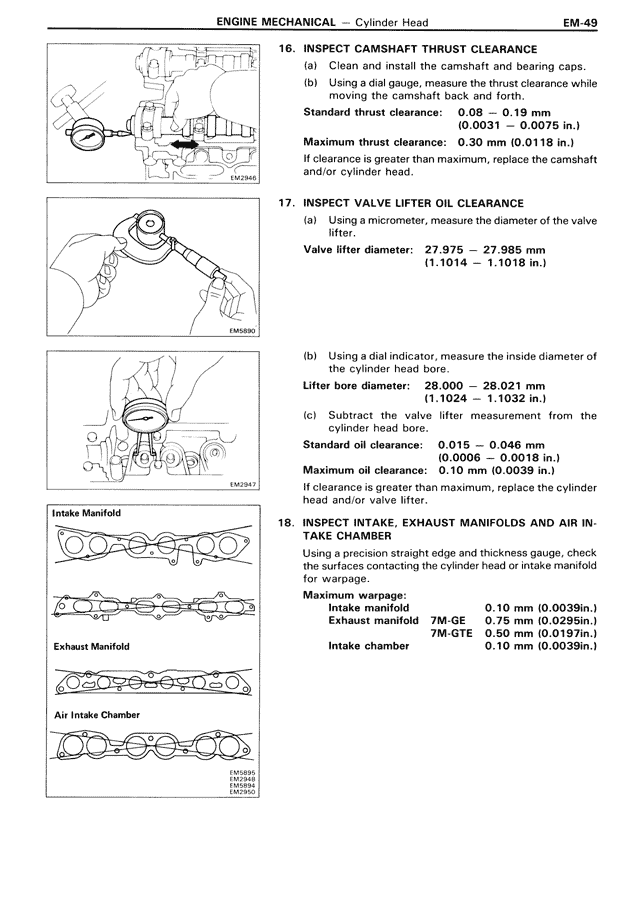

16. INSPECT CAMSHAFT THRUST CLEARANCE

(a) Clean and install the camshaft and bearing caps.

(b) Using a dial gauge, measure the thrust clearance while moving the camshaft back and forth.

Standard thrust clearance: 0.08 — 0.19 mm (0.0031 — 0.0075 in.)

Maximum thrust clearance: 0.30 mm (0.0118 in.)

If clearance is greater than maximum, replace the camshaft and/or cylinder head.

17. INSPECT VALVE LIFTER OIL CLEARANCE

(a) Using a micrometer, measure the diameter of the valve lifter.

Valve lifter diameter: 27.975 — 27.985 mm (1.1014 — 1.1018 in.)

(b) Using a dial indicator, measure the inside diameter of the cylinder head bore.

Lifter bore diameter: 28.000 — 28.021 mm (1.1024 — 1.1032 in.)

(c) Subtract the valve lifter measurement from the cylinder head bore.

Standard oil clearance: 0.015 — 0.046 mm (0.0006 — 0.0018 in.)

Maximum oil clearance: 0.10 mm (0.0039 in.)

If clearance is greater than maximum, replace the cylinder head and/or valve lifter.

18. INSPECT INTAKE, EXHAUST MANIFOLDS AND AIR IN-TAKE CHAMBER

Using a precision straight edge and thickness gauge, check the surfaces contacting the cylinder head or intake manifold for warpage.

Maximum warpage:

Intake manifold 0.10 mm (0.0039in.)

Exhaust manifold 7M-GE 0.75 mm (0.0295in.)

7M-GTE 0.50 mm (0.0197in.)

Intake chamber 0.10 mm (0.0039in.)

Intake Manifold

Exhaust Manifold

Air Intake Chamber

EM2682

EM2683

EM2684

EM2662