INSPECTION AND REPAIR OF CRANKSHAFT

1. INSPECT CRANKSHAFT FOR RUNOUT

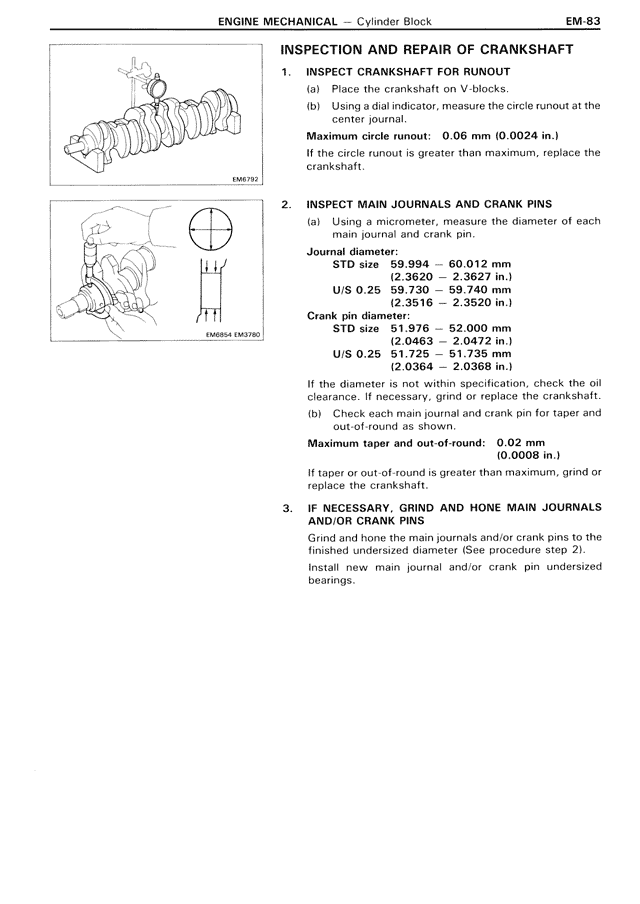

(a) Place the crankshaft on V-blocks.

(b) Using a dial indicator, measure the circle runout at the center journal.

Maximum circle runout: 0.06 mm (0.0024 in.)

If the circle runout is greater than maximum, replace the crankshaft.

2. INSPECT MAIN JOURNALS AND CRANK PINS

(a) Using a micrometer, measure the diameter of each main journal and crank pin.

Journal diameter:

STD size 59.994 — 60.012 mm

(2.3620 — 2.3627 in.)

U/S 0.25 59.730 — 59.740 mm

(2.3516 — 2.3520 in.)

Crank pin diameter:

STD size 51.976 — 52.000 mm

(2.0463 — 2.0472 in.)

U/S 0.25 51.725 — 51.735 mm

(2.0364 — 2.0368 in.)

If the diameter is not within specification, check the oil clearance. If necessary, grind or replace the crankshaft.

(b) Check each main journal and crank pin for taper and out-of-round as shown.

Maximum taper and out-of-round: 0.02 mm

(0.0008 in.)

If taper or out-of-round is greater than maximum, grind or replace the crankshaft.

3. IF NECESSARY, GRIND AND HONE MAIN JOURNALS AND/OR CRANK PINS

Grind and hone the main journals and/or crank pins to the finished undersize diameter (See procedure step 2).

Install new main journal and/or crank pin undersized bearings.