EM-86

ENGINE MECHANICAL — Cylinder Block

[DIAGRAM: Shows front mark, axial direction, oil hole, thrust direction, and DI hole positioning]

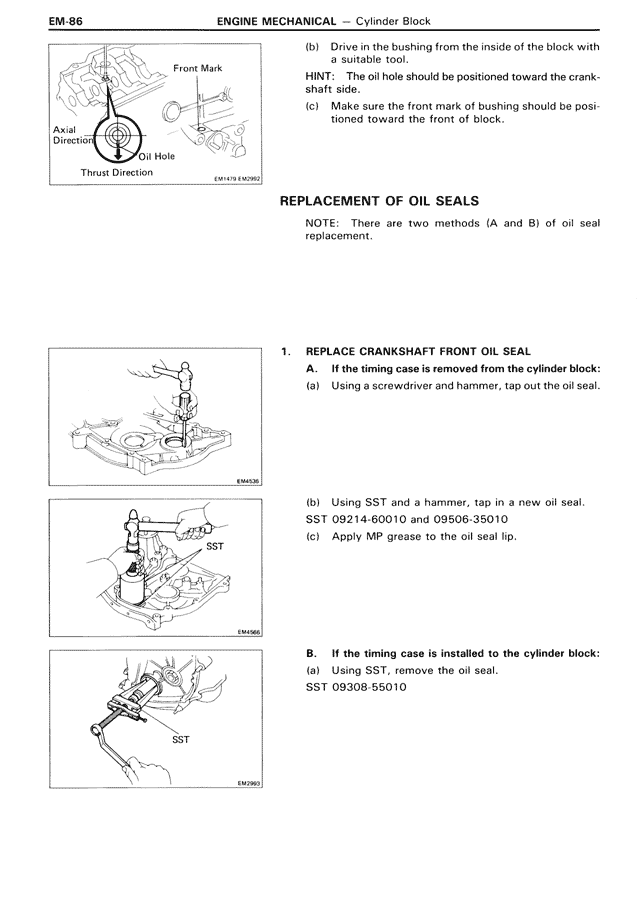

(b) Drive in the bushing from the inside of the block with a suitable tool.

HINT: The oil hole should be positioned toward the crankshaft side.

(c) Make sure the front mark of bushing should be positioned toward the front of block.

REPLACEMENT OF OIL SEALS

NOTE: There are two methods (A and B) of oil seal replacement.

1. REPLACE CRANKSHAFT FRONT OIL SEAL

A. If the timing case is removed from the cylinder block:

(a) Using a screwdriver and hammer, tap out the oil seal.

(b) Using SST and a hammer, tap in a new oil seal.

SST 09214-60010 and 09506-35010

(c) Apply MP grease to the oil seal lip.

B. If the timing case is installed to the cylinder block:

(a) Using SST, remove the oil seal.

SST 09308 55010