EM-92

ENGINE MECHANICAL — Cylinder Block

6. INSTALL PISTON AND CONNECTING ROD ASSEMBLIES

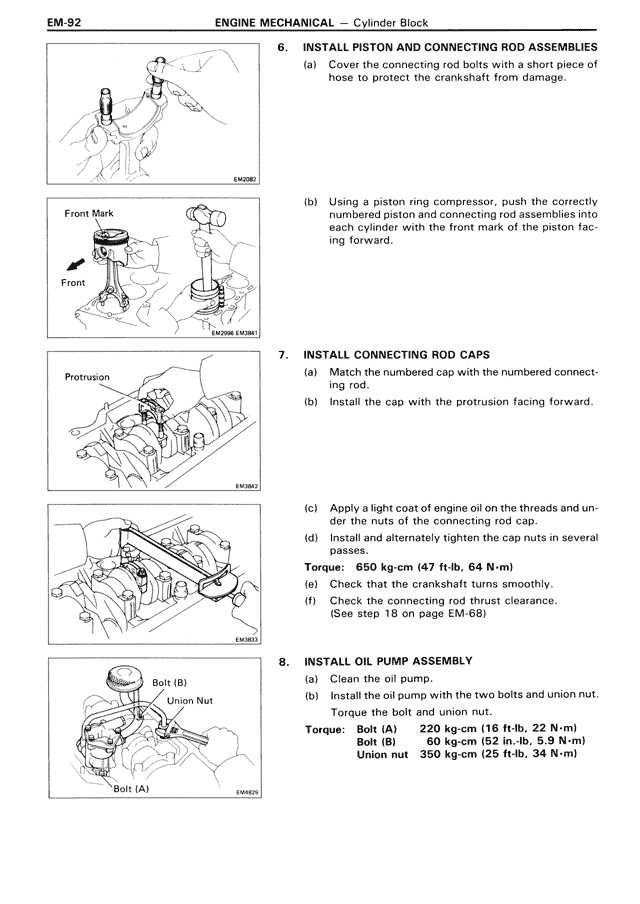

(a) Cover the connecting rod bolts with a short piece of hose to protect the crankshaft from damage.

(b) Using a piston ring compressor, push the correctly numbered piston and assemblies into each cylinder with the front mark of the piston facing forward.

Front Mark

Front

7. INSTALL CONNECTING ROD CAPS

(a) Match the numbered cap with the numbered connecting rod.

(b) Install the cap with the protrusion facing forward.

Protrusion

(c) Apply a light coat of engine oil on the threads and under the nuts of the connecting rod cap.

(d) Install and alternately tighten the cap nuts in several passes.

Torque: 650 kg-cm (47 ft-lb, 64 N·m)

(e) Check that the crankshaft turns smoothly.

(f) Check the connecting rod thrust clearance. (See step 18 on page EM-68)

8. INSTALL OIL PUMP ASSEMBLY

(a) Clean the oil pump.

(b) Install the oil pump with the two bolts and union nut.

Torque the bolt and union nut.

Torque: Bolt (A) 220 kg-cm (16 ft-lb, 22 N·m)

Bolt (B) 60 kg-cm (52 in.-lb, 5.9 N·m)

Union nut 390 kg-cm (28 ft-lb, 29 N·m)

Bolt (B)

Union Nut

Bolt (A)