EFI SYSTEM — Electronic Control System

Oxygen Sensor

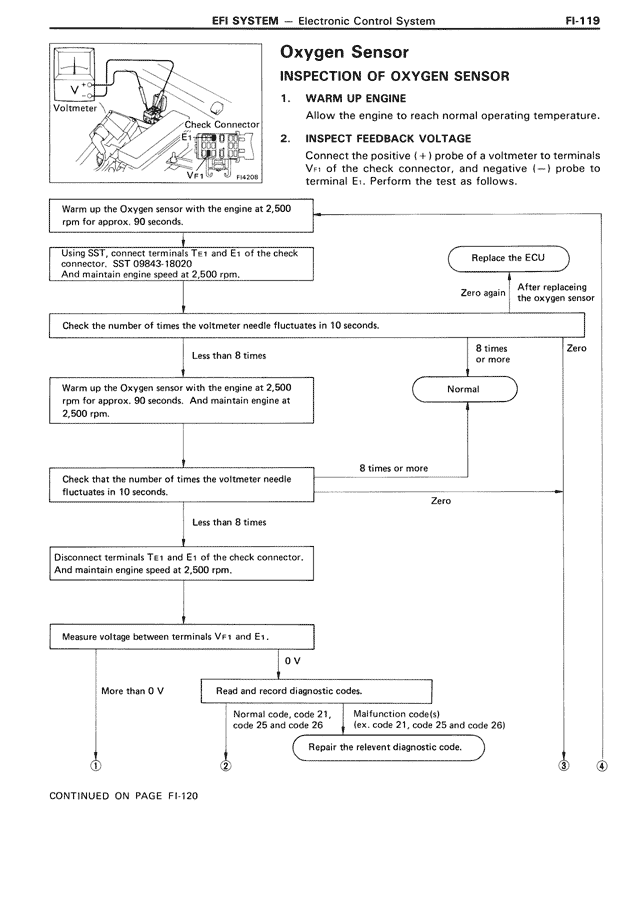

INSPECTION OF OXYGEN SENSOR

1. WARM UP ENGINE

Allow the engine to reach normal operating temperature.

2. INSPECT FEEDBACK VOLTAGE

Connect the positive (+) probe of a voltmeter to terminals V₊₁ of the check connector, and negative (−) probe to terminal E₁. Perform the test as follows.

Warm up the Oxygen sensor with the engine at 2,500 rpm for approx. 90 seconds.

Using SST, connect terminals T₊₁ and E₁ of the check connector. SST 09843-18020

And maintain engine speed at 2,500 rpm.

Check the number of times the voltmeter needle fluctuates in 10 seconds.

Less than 8 times → Warm up the Oxygen sensor with the engine at 2,500 rpm for approx. 90 seconds. And maintain engine at 2,500 rpm. → Check that the number of times the voltmeter needle fluctuates in 10 seconds. → Less than 8 times → Disconnect terminals T₊₁ and E₁ of the check connector. And maintain engine speed at 2,500 rpm. → Measure voltage between terminals V₊₁ and E₁. → 0 V / More than 0 V → Read and record diagnostic codes. → Normal code, code 21, code 25 and code 26 / Malfunction code(s) (ex. code 21, code 25 and code 26) → Repair the relevant diagnostic code.

8 times or more → Normal → After replacing the oxygen sensor → Zero again → Replace the ECU

8 times or more → Zero

Zero

CONTINUED ON PAGE FI-120