The clearance between the flow control valve and pump body installation hole is very important. After manufacture, the factory measures the size of the installation hole and outer circumference of the flow control valve, and punches a mark accordingly. Therefore, when replacing the flow control valve, be sure to do so with one having the same mark in order to insure the proper clearance.

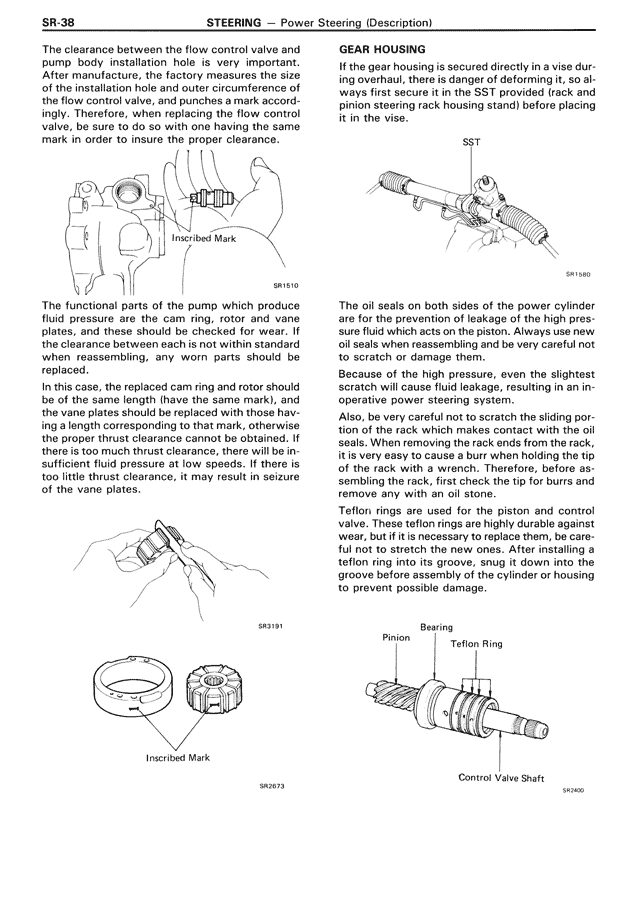

The traditional parts of the pump which produce fluid pressure are the cam ring, rotor and vane plates, and these should be checked for wear. If the clearance between each is not within standard when reassembling, any worn parts should be replaced.

In this case, the replaced cam ring and rotor should be of the same length (have the same mark), and the vane plates should be replaced with those having a length corresponding to that mark, otherwise the proper thrust clearance cannot be obtained. If there is too much thrust clearance, there will be insufficient fluid pressure at low speeds. If there is too little thrust clearance, it may result in seizure of the vane plates.

GEAR HOUSING

If the gear housing is secured directly in a vise during overhaul, there is danger of deforming it, so always first secure it in the SST provided (rack and pinion steering rack housing stand) before placing it in the vise.

The oil seals on both sides of the power cylinder are for the prevention of leakage of the high pressure fluid which acts on the piston. Always use new oil seals when reassembling and be very careful not to scratch or damage them.

Because of the high pressure, even the slightest scratch will cause fluid leakage, resulting in an inoperative power steering system.

Also, be very careful not to scratch the sliding portion of the rack which makes contact with the oil seals. When removing the rack ends from the rack, it is very easy to cause a burr when holding the tip of the rack with a wrench. Therefore, before assembling the rack, first check the tip for burrs and remove any with an oil stone.

Teflon rings are used for the piston and control valve. These teflon rings are highly durable against wear, but if it is necessary to replace them, be careful not to stretch the new ones. After installing a teflon ring into its groove, snug it down into the groove before assembly of the cylinder or housing to prevent possible damage.

Inscribed Mark

SR1610

SST

SR1640

Inscribed Mark

SR3073

Pinion

Bearing

Teflon Ring

Control Valve Shaft

SR2420

SR3191